Isibiyeli seMetal seSiko esineSiko esineCNC eChanekile kwiindawo ezininzi

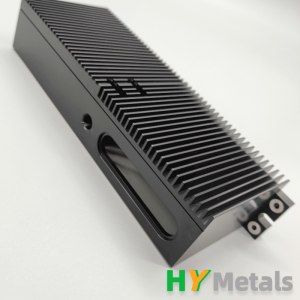

Kwi-HY Metals, siyazingca yethuIminyaka eyi-14 yamavakunye nokuzinikela ekunikezeleni ngowona mgangatho uphezuluukwenza isikoizisombululo. Ubuchule bethu buleleukuchaneka sheet metalukwenziwakwayeCNC Machining, kwaye sizimisele ukubonelela abathengi bethu ngeemveliso ezigqwesileyo kwiklasi ezihlangabezana neenkcukacha zabo ezichanekileyo.

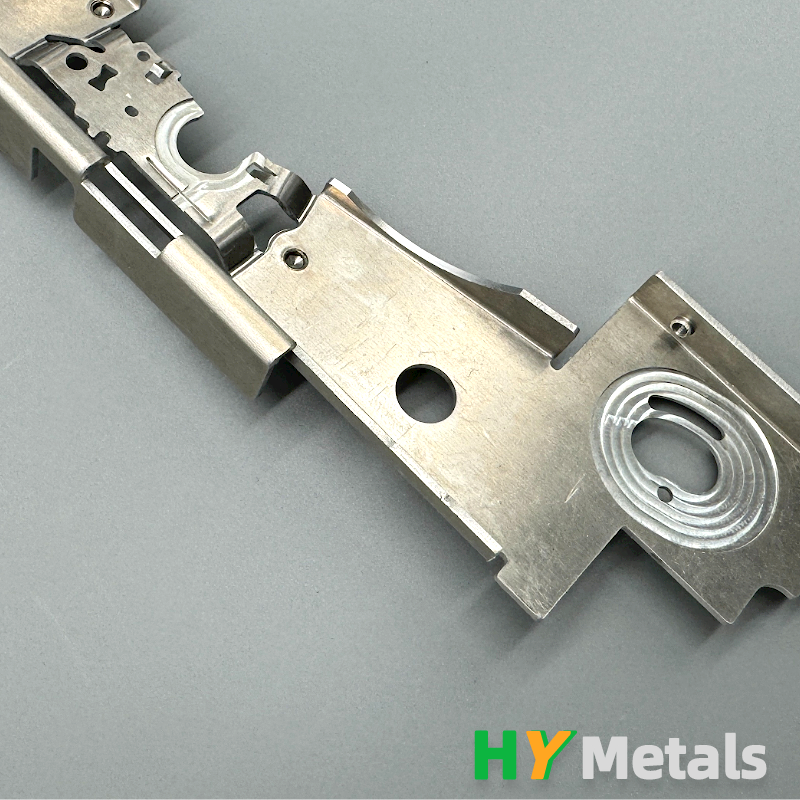

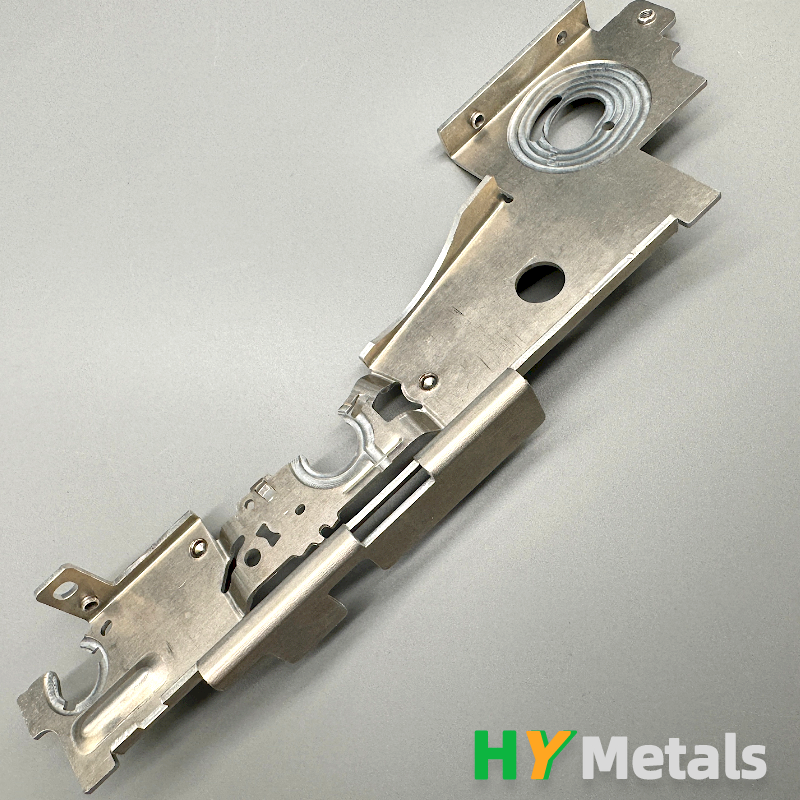

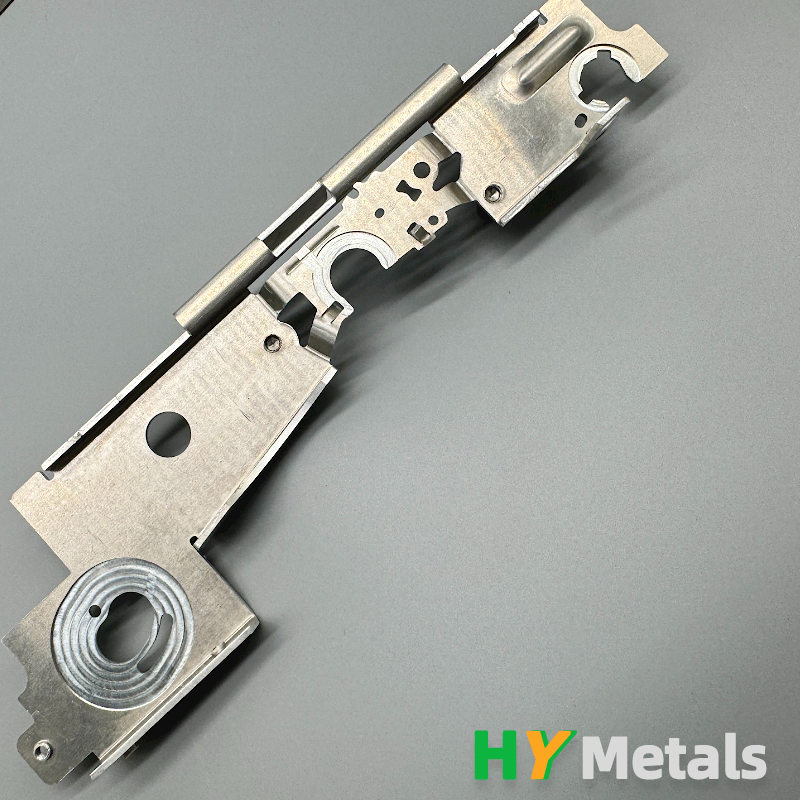

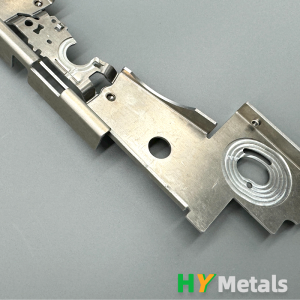

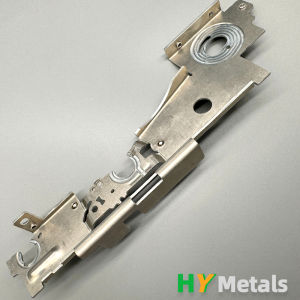

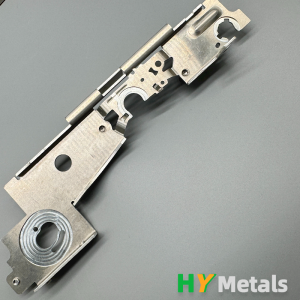

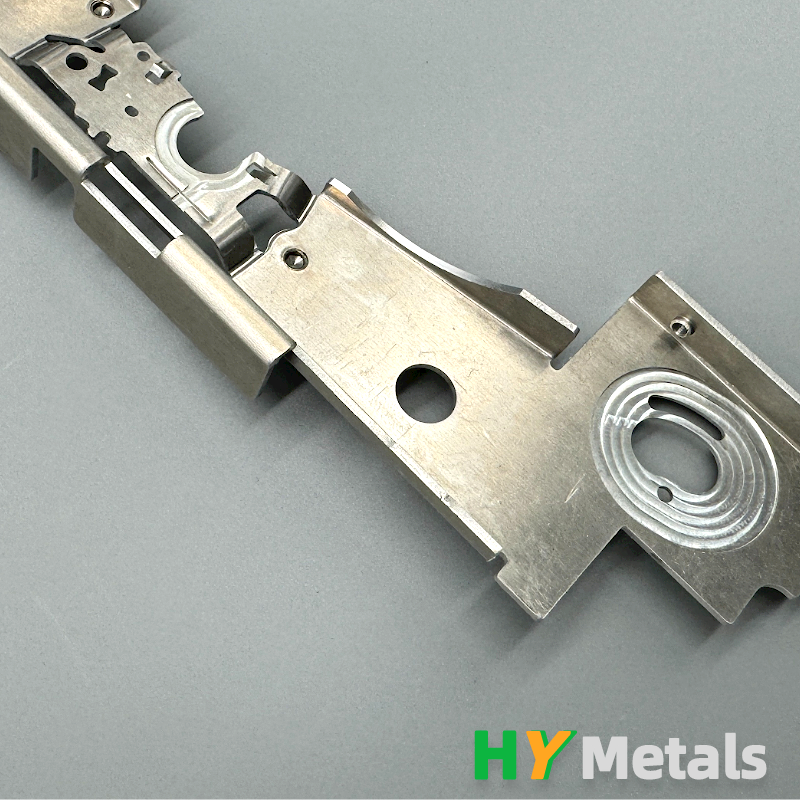

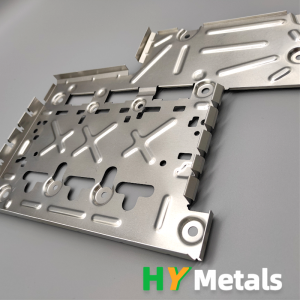

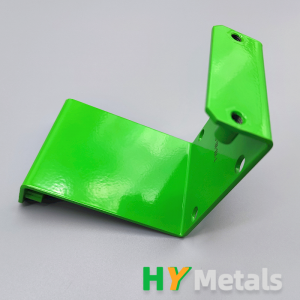

Iprojekthi yakutsha nje ebonisa amandla ethu ibandakanya ukuveliswa kweamalungu sheet metal isikoyenziwe Al5052 forizibiyeli zeemoto. Izibiyeli zihamba ngothotho lweenkqubo ezibandakanya ukusika i-laser, ukugoba kunye ne-riveting, ngaphambi kokufuna umatshini ochanekileyo kwiindawo ezine ezikhethekileyo ukwenza izangqa ezinyathelweyo. Le nkqubo ibalulekile ukulungelelanisa amacandelo e-elektroniki kwinqanaba elilandelayo lokuhlanganisa.

Umngeni wokugcina ukunyamezela komatshini emva kokugoba yingxaki eqhelekileyo kwishishini lesinyithi. Ngokungafaniyo nomatshini we-CNC, ukunyamezela kweengxenye zentsimbi akuqinanga kakhulu, kwaye emva kokugoba, kunzima ukukhusela inxalenye kumatshini we-CNC ukubeka ngokuchanekileyo. Nangona kunjalo, kwi-HY Metals, sinobuchwephesha kunye netekhnoloji yokoyisa le mingeni kwaye sifezekise iziphumo eziphezulu.

Ukukhusela iinxalenye zentsimbi kumatshini we-CNC kunokuba ngumngeni, kodwa kukho iindlela ezininzi kunye neengqwalasela ezinokuthi zincede ukuqinisekisa ukunyamezela komatshini.

1. Yiqinise ngokufanelekileyo: Sebenzisa i-clamp, ii-vises, okanye izilungiso eziqhelekileyo ukubambaishidi lentsimbingokukhuselekileyo endaweni. Xa uyila i-fixture, qwalasela ubukhulu bemathiriyeli, imilo, kunye noguquko olunokwenzeka ngexesha lokulungiswa.

2. Imihlathi ethambileyo:Ukuba usebenzisa i-vise, cinga ukusebenzisa imihlathi ethambileyo ukukhusela umonakalo okanye i-deformation ye-sheet metal. Imihlathi ethambileyo inokwenziwa ngoomatshini ukuze ihambelane neekhonto zenxalenye, ibonelela ngenkxaso engcono kunye nokunciphisa ukungcangcazela.

3. Iziseko zenkxaso:Kumacandelwana esinyithi amakhulu okanye antsonkothileyo, cinga ukusebenzisa izakhiwo zenkxaso okanye izixhobo ezongezelelweyo zokunciphisa ukuphambuka ngexesha lomatshini.

4. Amanqaku ezalathiso:Ukuseka amanqaku acacileyo ereferensi kumacandelo esinyithi ukuqinisekisa ukuma okuhambelanayo kunye nokulungelelaniswa ngexesha lokucubungula. Oku kubalulekile ukugcina ukunyamezelana okuqinileyo.

5. Iqhinga lokubamba:Phuhlisa iqhinga lokubamba elisasaza ngokulinganayo amandla okubamba phezu kwenxalenye ukunciphisa inguquko. Cinga ukusebenzisa i-clamps ephantsi okanye i-edge clamps ukuphepha ukuphazamiseka kwezixhobo zokusika.

6. Usetyenziso lwendlela yesixhobo:Sebenzisa isoftware yeCAM ukuvelisa iindlela zesixhobo ezinciphisa ukungcangcazela kunye nokuphambuka kwesixhobo, ngakumbi xa usenza iinxalenye zentsimbi ezicekethekileyo okanye ezibuthathaka.

7. Ukuhlolwa kunye nengxelo:Ukuphumeza inkqubo yokuhlola eyomeleleyo ukuqinisekisa ukuchaneka kweempawu zomatshini. Sebenzisa impendulo evela kwiziphumo zohlolo ukucokisa ukulungiswa kunye nobuchule bomatshini bokuqhuba imveliso yexesha elizayo.

Ngokujongana nale miba, abavelisi banokuphucula ukuchaneka kunye nokuhambelanaCNC machining yamacandelo sheet metal, ekugqibeleni uqinisekisaukunyamezela okuqinileyo ziyafezekiswa.

Kunye neqela labasebenzi abaqeqeshwe kakuhle abangaphezulu kwama-350 kunye nezakhiwo zangoku ezixhotyiswe ngoomatshini abangaphezu kwama-500., siyakwazi ukusingatha iiprojekthi zaluphi na ubungakanani. Nokuba ngumzekelo omnye okanye uthotho lwemveliso yamawaka, sizibophelele ekuboneleleni ngezona ndawo zikumgangatho ophezulu kumashishini ahlukeneyo.

Ukuzinikela kwethu ekugqweseni nasekuthatheni ingqalelo kwiinkcukacha kubonakaliswe ekuphumezeni ngempumelelo iprojekthi yesibiyeli semoto yakho. Nangona ubunzima benkqubo yokugoba emva kokugoba, siqinisekisa ukuba iibrakethi zentsimbi ezigqityiweyo zidibana nemigangatho ephezulu yokuchaneka kunye nomgangatho.

Xa ukhetha i-HY Metals kwiimfuno zakho zokwenza isiko, unokulindela:

1. Ukwenziwa kwentsimbi echanekileyo kunye nobuchule bomatshini beCNC

2. Iqela elizinikeleyo lizinikele ekuboneleleni ngeemveliso ezisemgangathweni

3. Ukukwazi ukuphatha iiprojekthi zaluphi na ubungakanani, ukusuka kwiprototyping ukuya kwimveliso yobuninzi

4. Ingqalelo kwiinkcukacha kunye nokuzinikela ekuhlangabezaneni neenkcukacha zakho ngqo

Nokuba ufunaiindawo zentsimbi ezichanekileyo, prototypes sheet metal, ngokuchanekileyo machining or izisombululo zokwenziwa kwesiko, I-HY Metals liqabane lakho elithembekileyo. Qhagamshelana nathi namhlanje ukuxoxa ngeemfuno zeprojekthi yakho kwaye ube namava umahluko owenziwe bubuchule bethu kunye nokuzinikela kwethu ekunikezeni iziphumo ezibalaseleyo.