Isitampu sesinyithi yinkqubo enoomatshini bokushicilela kunye neZixhobo zokuvelisa ngobuninzi.Ichaneke ngakumbi, ikhawuleza ngakumbi, izinzile, kwaye ixabiso leyunithi litshiphu ngakumbi kunokusika i-laser kunye nokugoba ngoomatshini bokugoba.Ewe kufuneka uqwalasele iindleko zezixhobo kuqala.

Ngokutsho kolwahlulo, i-Metal stamping yahlulwe yaba yinto eqhelekileyoIsitampu,Umzobo onzulukwayeUkubetha kwe-NCT.

Umfanekiso woku-1: Ikona enye ye-HY Metals stamping workshop

I-Metal Stamping ineempawu zesantya esiphezulu kunye nokuchaneka.Ukunyamezela ukusika ukunyamezela kunokufikelela kwi-± 0.05mm okanye ngaphezulu, ukunyamezela ukugoba ukunyathela kunokuba ± 0.1mm okanye ngcono.

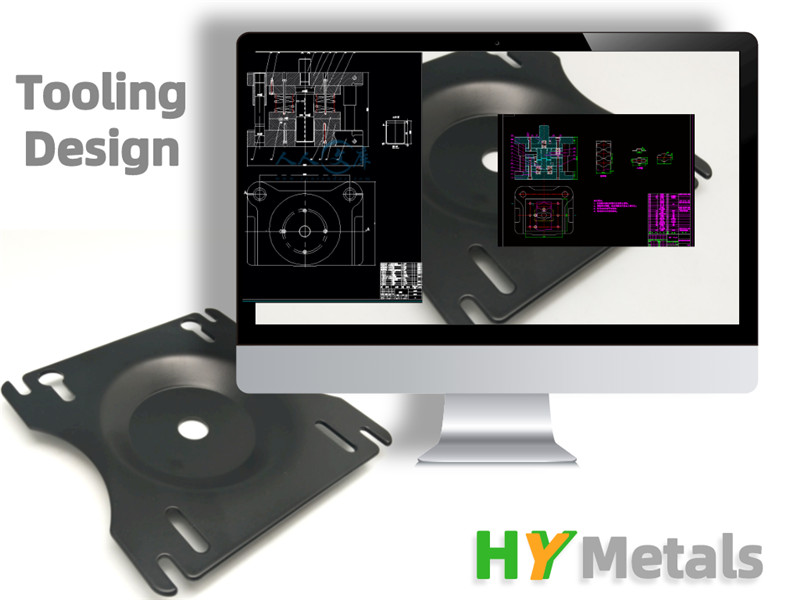

Uyilo lweSitampu sezixhobo

Uya kudinga izixhobo zesitampu ukwenza iinxalenye xa ubuninzi bebhetshi bungaphezulu kwe-5000pcs, okanye xa kubiza ukwenziwa ngomatshini wokusika we-laser kunye nokugoba.

Iqela leenjineli ze-HY Metals liya kuhlalutya icandelo lakho lentsimbi kwaye liyile esona sixhobo sesitampu ngokuhambelana nemizobo yemveliso yakho kunye nohlahlo lwabiwo mali lwakho.

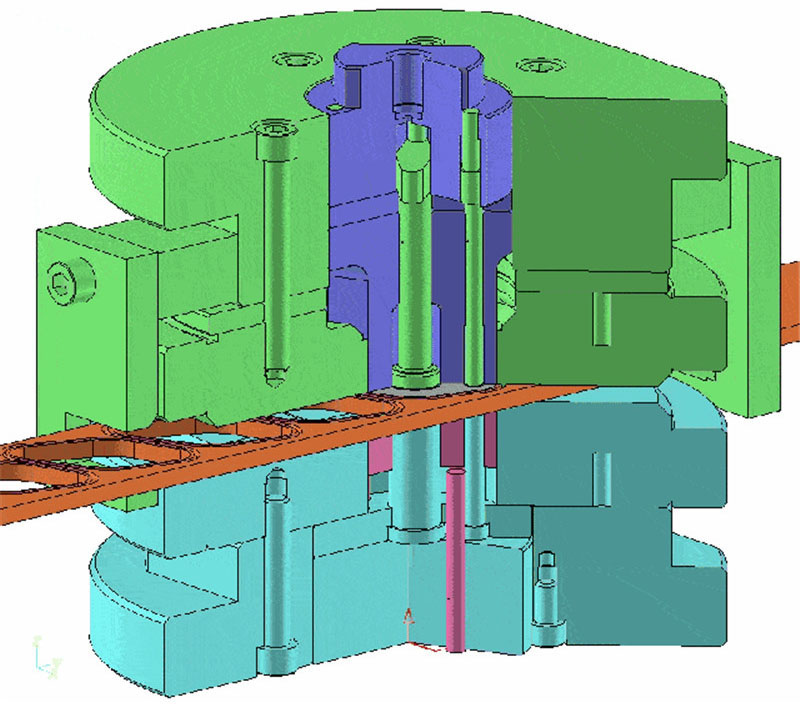

Umfanekiso 2: Sinenkxaso eyomeleleyo yenjineli yoyilo lokungunda

Inokuba yi-Progressive-die okanye uthotho lokufa kwe-punch enye exhomekeke kwisakhiwo, ubuninzi, ixesha eliphambili kunye nexabiso elifunayo.

I-Progressive-die yi-stamping mold eqhubekayo enokugqiba zonke okanye iinkqubo ezininzi ngexesha elinye.Unokufuna nje iseti e-1 eqhubekayo yokufa ukuze ufumane indawo egqityiweyo.

Umfanekiso wesi-3: Lo ngumzekelo wokufa okulula okuqhubekekayo, ukusika nokugoba kube kanye.

I-punch enye yokufa yinkqubo yokunyathela inyathelo ngenyathelo.Isenokuba nesixhobo sokusika isitampu kunye nezixhobo ezininzi zokugoba.

Izixhobo zepunch enye kulula ukuzisebenzisa kwaye zihlala zitshiphu kunezixhobo eziqhubekayo.Kodwa iyacotha kwimveliso yobuninzi kwaye iindawo ezinesitampu ziya kuba nexabiso leyunithi ephezulu.

Ukusika isitampu

Ngokuqhelekileyo ukusika isitampu linyathelo lokuqala lokusika imingxuma okanye iimilo.

Ukusika ngokusebenzisa isitampu sezixhobo kukhawuleza kwaye kubiza kakhulu kunokusika ngelaser.

Ukwenziwa kwesitampu

Ulwakhiwo oluthile lweconcave kunye neconvex okanye iimbambo zamalungu athile entsimbi, siya kufuna isitampu sesixhobo ukuze sizenze.

Ukugoba isitampu

Ukugoba isitampu nako kunexabiso eliphantsi kwaye ngokukhawuleza kunoomatshini bokugoba.Kodwa ilungele kuphela iindawo ezinokwakheka okuntsokothileyo kunye nobukhulu obuncinci njenge-300mm * 300mm.Kuba xa ubungakanani bokugoba bukhulu iindleko zezixhobo ziya kuba phezulu.

Ke ngamanye amaxesha ubungakanani obukhulu kunye namalungu amakhulu, siyila kuphela isixhobo sokusika isitampu, akukho sixhobo sokugoba.Siya kugoba iindawo nje ngoomatshini bokugoba.

Sineenjineli ezi-5 zobuchwephesha boyilo oluya kunika ezona zisombululo zilungileyo zamalungu akho esitampu sesinyithi.

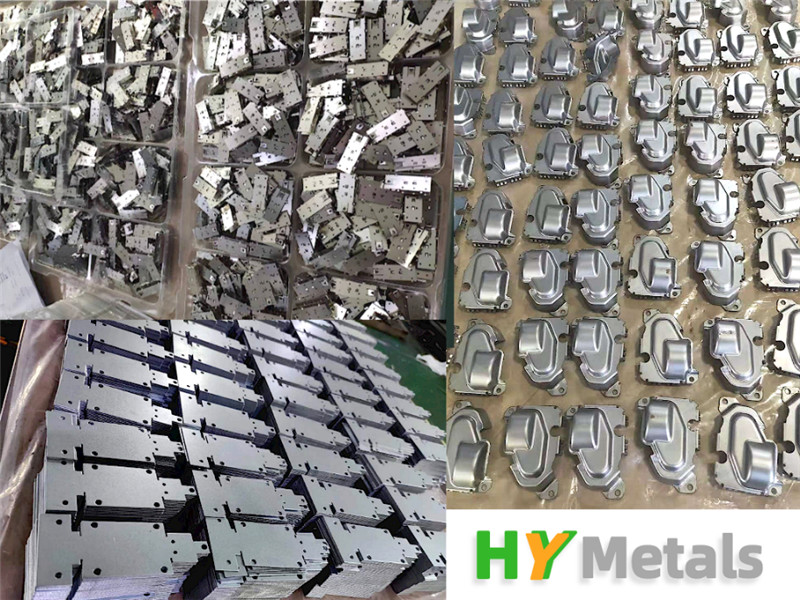

Umfanekiso 4: HY Izinyithi zigximfiza indawo yokugcina izixhobo

Sineeseti ezingaphezu kwama-20 zokunyathela kunye noomatshini bokubetha ukusuka kwi-10T ukuya kwi-1200T yesitampu sesinyithi.Senze amakhulukhulu obumba bokubumba endlwini, kwaye safaka isitampu sezigidi zamalungu entsimbi achanekileyo kubathengi kwihlabathi liphela minyaka le.

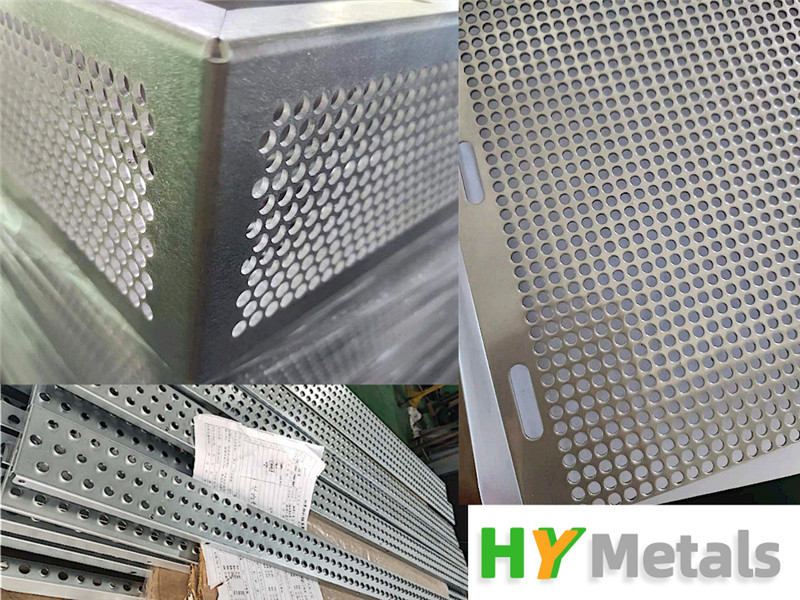

UMfanekiso5: Ezinye iindawo ezinesitampu ngeentsimbi ze-HY

Ke ngamanye amaxesha ubungakanani obukhulu kunye namalungu amakhulu, siyila kuphela isixhobo sokusika isitampu, akukho sixhobo sokugoba.Siya kugoba iindawo nje ngoomatshini bokugoba.

Sineenjineli ezi-5 zobuchwephesha boyilo oluya kunika ezona zisombululo zilungileyo zamalungu akho esitampu sesinyithi.

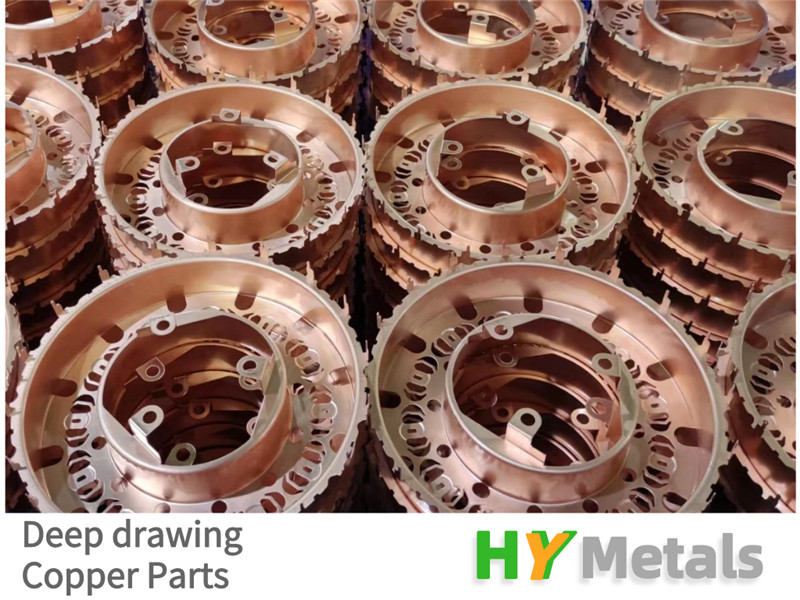

Umfanekiso 6: Umzobo onzulu kunye nesitampu seendawo zobhedu

Le yinxalenye yobhedu yokuzoba kunye nesitampu.

Siye sayila iiseti ezisi-7 zizonke izixhobo zepunch kule nxalenye kubandakanya iiseti ezi-3 ezinzulu zokuzoba ukwenza kunye ne-4 isitampu sesixhobo sokusika kunye nokugoba.

Umfanekiso we-7: Ezinye iimveliso ze-NCT zibethelwa ngenqindi nge-HY Metals

NCT Punching

I-punch ye-NCT imfutshane kwi-Numerical Control Turret Punch Press, eyaziwa ngokuba yi-Servo Punch, eqhubeka nomatshini ozenzekelayo kunye nenkqubo yokulawula i-industrial.

I-NCT punch ikwaluhlobo lwenkqubo ebandayo yokucofa.Iqhele ukusetyenziselwa ukusika eminye imingxunya yeMesh okanye imingxunya ye-OB.

Kwimicu yentsimbi enemingxuma emininzi, i-NCT punching iya kuba yinto engcono ngexabiso eliphantsi kunye nesantya esikhawulezayo kunokusika i-laser.

Kwaye siyazi ukuba ukusika kwe-laser kuya kukhokelela ekuguqulweni kobushushu.

I-NCT punch yinkqubo ebandayo engayi kukhokelela kuyo nayiphi na inguquko yobushushu kwaye iya kugcina ipleyiti yentsimbi njengento ecaba ngcono.