Ukuchaneka ngokwesiko kwe-CNC enziwe ngomatshini iinxalenye ze-Titanium ezinokujika

Ubunzima kwiCNCmachining kunye anodizing iindawo ingxubevange Titanium

CNC Machiningye-titanium alloys inikezela ngeseti eyodwa yemingeni ngenxa yeempawu zendalo zemathiriyeli. I-Titanium yaziwa ngomlinganiselo wayo ophezulu wamandla-kubunzima, ukuxhathisa ukubola, kunye ne-biocompatibility, iyenza ibe lukhetho oludumileyo kwi-aerospace, unyango, kunye nosetyenziso lweemoto. Nangona kunjalo, ezi mpawu zifanayo zenza nzima inkqubo yomatshini.

Ukusetyenzwa kwemingeni

1. Isinxibo sesixhobo:Iialloyi ze-Titanium ziyaziwa ngokuba zi-abrasive, ezibangelaukunxiba isixhobo ngokukhawuleza. Amandla aphezulu e-Titanium athetha ukuba izixhobo zokusika kufuneka zenziwe ngezinto eziphambili ezifana ne-carbides okanye i-ceramics ukumelana noxinzelelo olubandakanyekayo. Nokuba ngezi zixhobo, ubomi besixhobo bunokuba bufutshane kakhulu kunaxa kusetyenzwa ngeentsimbi ezithambileyo.

2. Ubushushu:I-Titanium ine-conductivity ephantsi ye-thermal, oku kuthetha ukuba ubushushu obuveliswa ngexesha lokucubungula abupheli ngokukhawuleza. Oku kubangela ukuguqulwa kwe-thermal ye-workpiece kunye nesixhobo sokusika, okukhokelela ekugqityweni komphezulu ombi kunye nokungachaneki kwe-dimensional. Izicwangciso zokupholisa ezisebenzayo, ezifana nokusetyenziswa kweenkqubo zokupholisa zoxinzelelo oluphezulu, zibalulekile ekudambiseni le ngxaki.

3. Ukwenziwa kweChip:Indlela iitshiphusi ze-titanium ezenza ngexesha lomatshini nazo zinokubangela iingxaki. Ngokungafaniyo neentsimbi ezithambileyo ezivelisa iitshiphusi eziqhubekayo, i-titanium ivelisa iitshiphusi ezimfutshane ezicolekileyo ezinokudityaniswa nesixhobo okanye isixhobo sokusebenza, nto leyo eyenze nzima ngakumbi inkqubo yomatshini.

4. Machining Parameters:Ukukhetha isantya esichanekileyo sokusika, izinga lokutya kunye nobunzulu bokusika kubalulekile. Iiparamitha ezinobundlongondlongo kakhulu zinokukhokelela ekohlulekeni kwesixhobo, ngelixa useto olugcina kakhulu lunokukhokelela kumatshini ongasebenziyo kunye nokwanda kwexesha lemveliso. Ukufumana eyona bhalansi ilungileyo kufuna amava abanzi kunye novavanyo.

5. Ukubamba iWorkpiece:I-Titanium inemodyuli ephantsi yokwaluka, okuthetha ukuba iya konakala phantsi koxinzelelo, yenze i-workpiece ibambe umngeni. Izixhobo ezikhethekileyo kunye neendlela zokubambelela zihlala zifunwa ukuqinisekisa ukuba iindawo zihlala zizinzile ngexesha lomatshini, oko kunokongeza ubunzima kunye neendleko kwinkqubo.

Anodizing Challenge

Emva kokoCNCukwenziwa kwe-machining kugqityiwe, ukwenza i-anodizing i-titanium alloy yenza nzima ngakumbi inkqubo yokuvelisa.Anodizingyinkqubo ye-electrochemical eyenza ukuxhathisa ukubola kwaye inike ukugqiba okuhle. Nangona kunjalo, i-anodizing titanium iza neseti yobunzima bayo.

1. Ukulungiswa komphezulu:Umphezulu we-titanium kufuneka ulungiswe ngononophelo ngaphambi kokuba i-anodizing. Naziphi na izinto ezingcolisayo, ezifana neoli okanye ii-residues zokucubungula, zinokubangela ukubambelela kakubi kwe-anodized layer. Oku kudla ngokufuna iinkqubo ezongezelelweyo zokucoca, ezifana nokucoca i-ultrasonic okanye i-chemical etching, eyandisa ixesha lokuvelisa kunye neendleko.

2. Ulawulo lwenkqubo ye-anodizing:Inkqubo ye-anodizing ye-titanium inovakalelo kwiiparamitha ezahlukeneyo, kubandakanywa amandla ombane, ubushushu kunye nokwakheka kwe-electrolyte. Ukufezekisa umaleko we-anodized ofanayo kufuna ulawulo oluchanekileyo lwezi zintlukwano. Ukwahluka kunokubangela umbala ongahambelaniyo kunye nobukhulu, obungamkelekanga kwizicelo ezichanekileyo.

3. Ukuhambelana kombala:I-titanium ye-Anodized inokuvelisa uluhlu lwemibala ngokuxhomekeke kubukhulu be-anodized layer. Nangona kunjalo, ukufumana umbala ongaguqukiyo kwiindawo ezininzi kunokuba ngumngeni ngenxa yokwahluka kokugqitywa komphezulu kunye nobukhulu. Oku kungahambelani kunokuba yingxaki kwizicelo apho ukufana kobuhle kubalulekile.

4. Unyango lwasemva kwe-anodizing:Emva kwe-anodizing, unyango olongezelelweyo lunokufuneka ukunyusa ukusebenza kwe-anodized layer. Oku kunokubandakanya iinkqubo zokutywinwa, ezinokuthi ziqhube nzima ngakumbi ukuhamba komsebenzi kunye nokwandisa ixesha lokuvelisa.

Ukuququmbela

Umatshini we-CNC kunye ne-anodizing elandelayo ye-titanium alloys ziinkqubo ezinzima ezifuna ulwazi olukhethekileyo, izixhobo kunye nobuchwepheshe. Imingeni enxulumene nomatshini, njengokunxiba izixhobo, ukuveliswa kobushushu kunye nokwakhiwa kwetshiphu, kunye nobunzima be-anodizing, kugxininise isidingo sokucwangciswa ngononophelo kunye nokwenziwa. Njengoko imfuno yamacandelo e-titanium esebenza ngokuphezulu iqhubeka nokukhula kuwo wonke amashishini, ukoyisa obu bunzima kubalulekile kubavelisi abajolise ekufezekiseni umgangatho ongqongqo kunye nemigangatho yokusebenza.

I-HY Metals yingcaphephe kwi-CNC machining eneminyaka engaphezu kwe-14, senze ngomatshini iindawo ezininzi ze-Titanium ngokuchanekileyo kunye nomgangatho olungileyo.

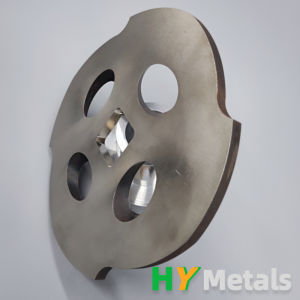

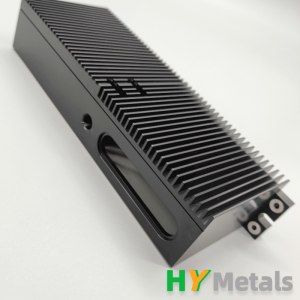

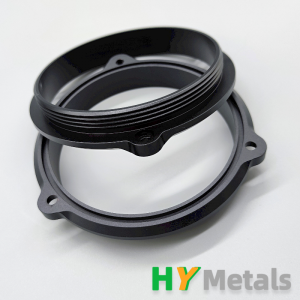

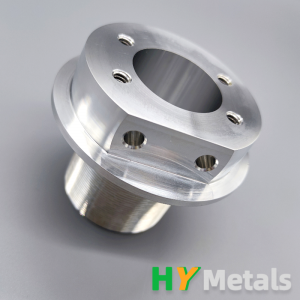

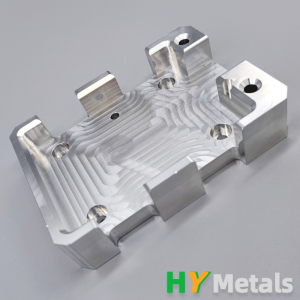

Naba abanye abatsha abafikayoCNC ngomatshini iinxalenye zeTitaniumyenziwe yi-HY Metals.

HY Iintsimbibonelelaindawo enyeiinkonzo zokwenza isiko kuqukaukwenziwa kwamaphepha esinyithi kwayeCNC Machining, 14 iminyaka yamava kunyeZisi-8 izakhiwo ezizezabantu ngokupheleleyo.

EgqwesileyoUmgangathoulawulo,mfutshaneJika ujonge ngemva,kakhuluunxibelelwano.

Thumela iRFQ yakho ngeimizobo eneenkcukachanamhlanje. Siza kukucaphulela ngokukhawuleza.

WeChat:na09260838

Xelela:+86 15815874097

I-imeyile:susanx@hymetalproducts.com