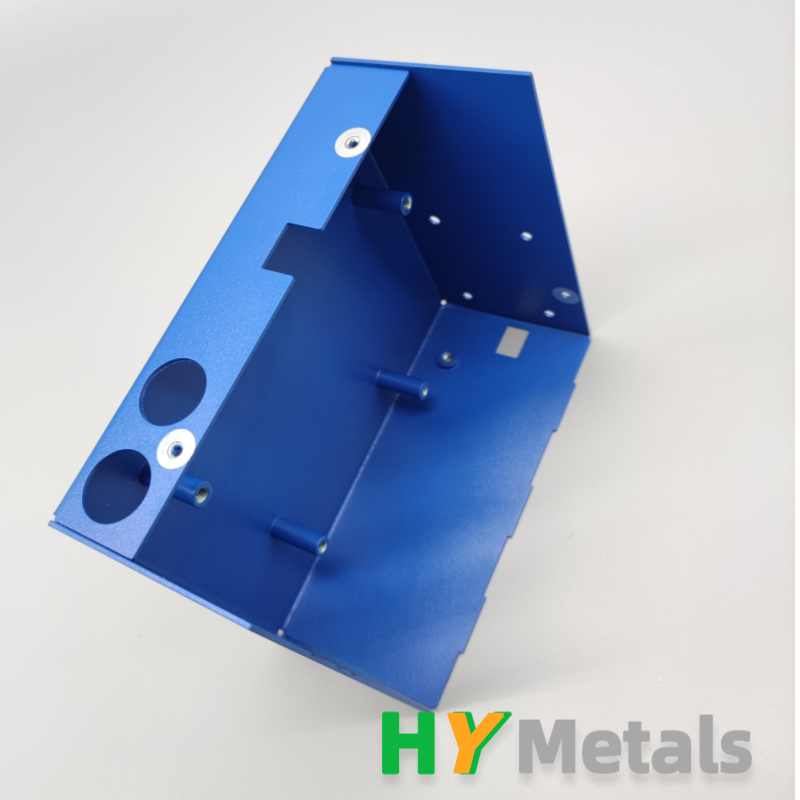

Iinxalenye zentsimbi ezenziwe ngokwezifiso ezifuna ukuba kungabikho ukutyabeka kwiindawo ezichaziweyo

Inkcazo

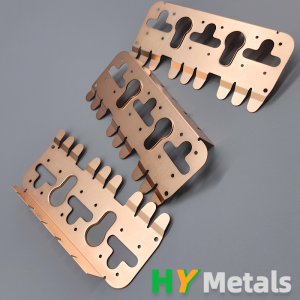

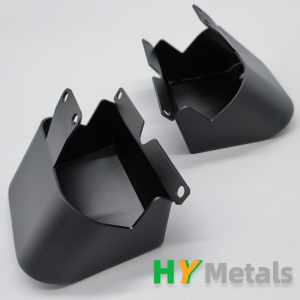

| Igama lenxalenye | Amacandelo esinyithi esiko kunye nokwaleka |

| Umgangatho okanye uLungiselelwe | Amacandelo esinyithi enziwe ngokwezifiso kunye neenxalenye zoomatshini ze-CNC |

| Ubungakanani | Ngokwemizobo |

| Ukunyamezelana | Ngokwemfuno yakho, kwimfuno |

| Izinto eziphathekayo | Aluminiyam, intsimbi, intsimbi engatyiwa, ubhedu, ubhedu |

| Umphezulu uGqiba | Ukugquma umgubo, i-plating, i-anodizing |

| Isicelo | Kuluhlu olubanzi lweshishini |

| Inkqubo | CNC machining, sheet metal eyenziwe |

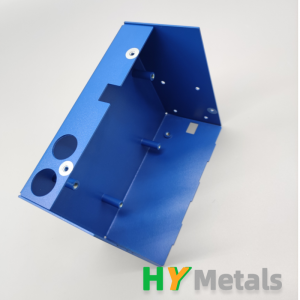

Indlela yokujongana Akukho mfuneko zokugquma kwindawo echaziweyo kwiindawo zentsimbi

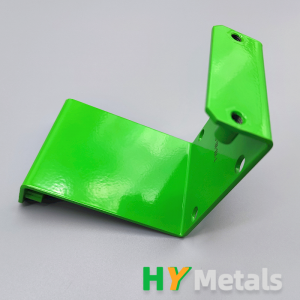

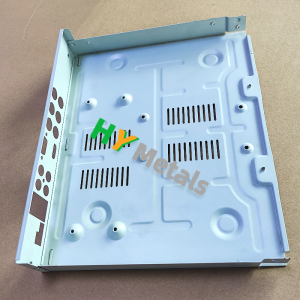

Xa kuziwa kwiindawo zetsimbi, iingubo zikhonza iinjongo ezininzi eziphambili. Iphucula ukubonakala kwamalungu, ikhusela kwizinto zangaphandle ezifana nokugqwala kunye nokunxiba, kwaye yandisa ubomi babo benkonzo. Ngokuqhelekileyo, iinxalenye zetsimbi zifakwe ngumgubo, zifakwe i-anodized okanye i-plated. Nangona kunjalo, ezinye i-sheet metal okanye i-CNC machined parts zinokufuna ukuba umhlaba wonke ugqunywe ngaphandle kwezo ndawo xa i-conductivity ifuneka kwiindawo ezithile zenxalenye.

Kule meko, kuyimfuneko ukugubungela ezo ndawo ezingadingi ukugquma. Ukugquma kufuneka kwenziwe ngononophelo ukuqinisekisa ukuba iindawo ezigqunyiweyo azinapeyinti kwaye iindawo eziseleyo zigqunywe ngokugqibeleleyo. Nazi ezinye iingcebiso zokuqinisekisa ukuba inkqubo yokwaleka ihamba kakuhle.

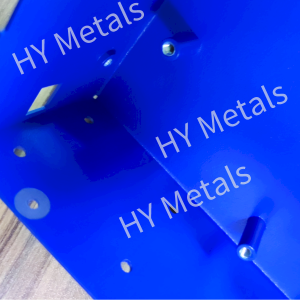

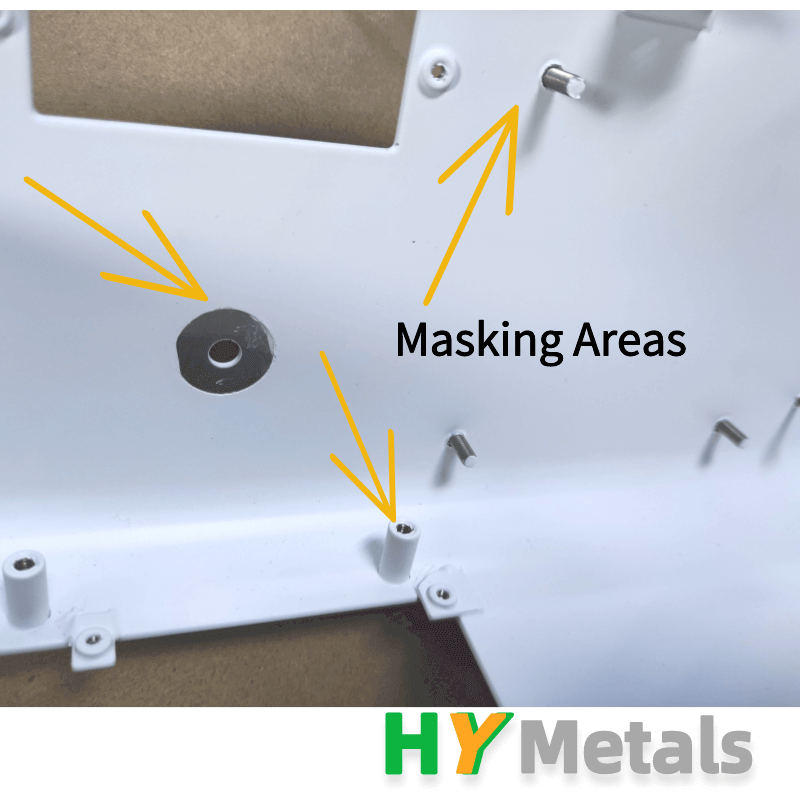

Ukufihla ipeyinti

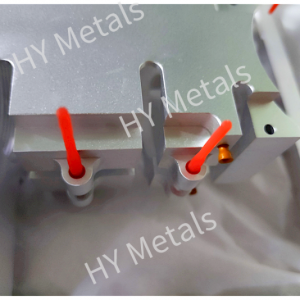

Xa i-powder igubungele, ukugubungela indawo nge-tape yeyona ndlela ilula kakhulu yokukhusela iindawo ezingafakwanga. Okokuqala, umphezulu kufuneka ucocwe ngokufanelekileyo kwaye emva koko ugqunywe ngeteyiphu okanye nayiphi na ifilimu ye-thermoplastic enokumelana nokushisa okuphezulu. Emva kokugubungela, i-tape kufuneka isuswe ngokucophelela ukwenzela ukuba i-coating ingaphumi. Ukugubungela kwinkqubo yokugqoka umgubo kufuna ukuchaneka ukuphucula umgangatho wemveliso yokugqibela.

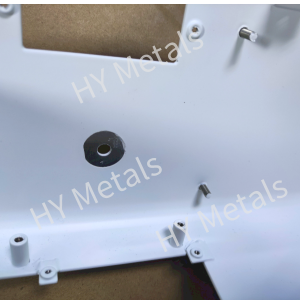

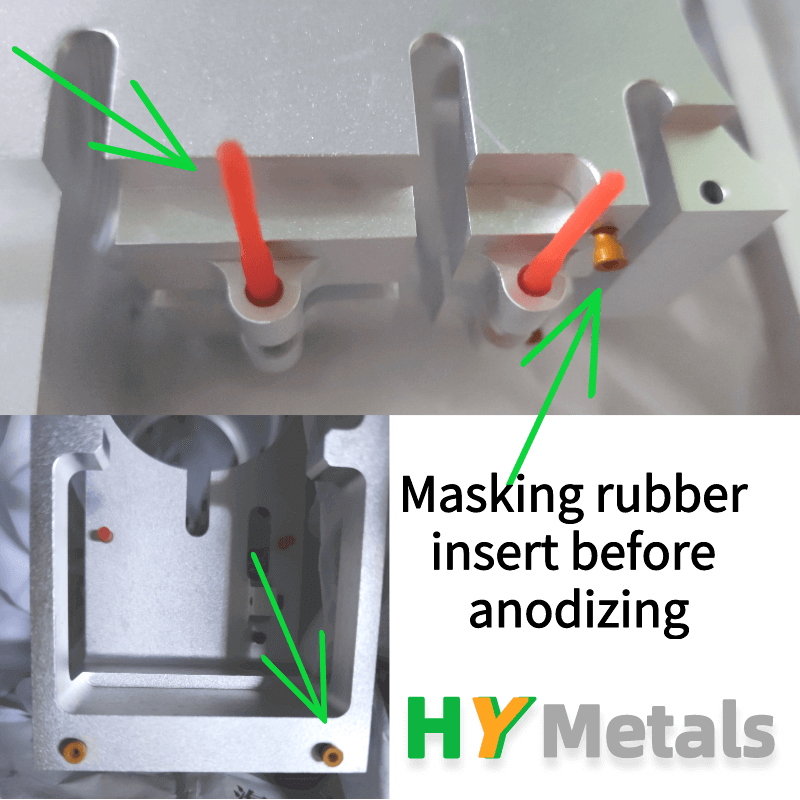

Anodizing kunye noPlating

Ngexesha lenkqubo ye-anodizing iinxalenye ze-aluminiyam, umaleko we-oxide wenziwa kumphezulu wesinyithi ophucula inkangeleko ngelixa unikezela ukuxhathisa ukubola. Kwakhona, sebenzisa i-anti-oxidant glue ukukhusela inxalenye ngexesha lenkqubo yokufihla. Amalungu e-aluminium anodized anokuthi agqunywe ngokusebenzisa izinto zokuncamathelisa ezifana ne-nitrocellulose okanye ipeyinti.

Xa ubeka iindawo zetsimbi, kuyimfuneko ukugubungela imicu yamantongomane okanye i-studs ukuphepha ukugquma. Ukusebenzisa ukufakwa kwerabha kuya kuba sisisombululo sokufihla imingxuma, evumela ukuba imisonto ibaleke inkqubo yokucwenga.

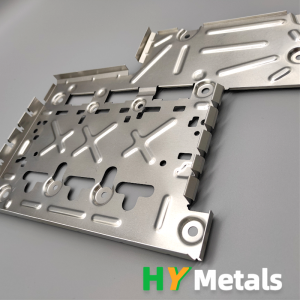

Amalungu esinyithi esiko

Xa kusenziwa iinxalenye zentsimbi yesiko, kubalulekile ukuqinisekisa ukuba iinxalenye ziyahlangabezana nemigaqo echanekileyo yomthengi. Ubuchule bokufihla obuchanekileyo bubaluleke kakhulu kwintsimbi yentsimbi kunye neendawo zoomatshini ze-CNC ezingadingi kugqunywa kwiindawo ezithile. Iingubo ezichanekileyo zobunjineli zithetha ukunikela ingqalelo kwiinkcukacha ezintsonkothileyo kunye nomgangatho wezinto ezisetyenzisiweyo. Emva kwakho konke, iimpazamo zokugubungela zingakhokelela kwiindawo ezichithwayo kunye neendleko ezongezelelweyo ezingalindelekanga.

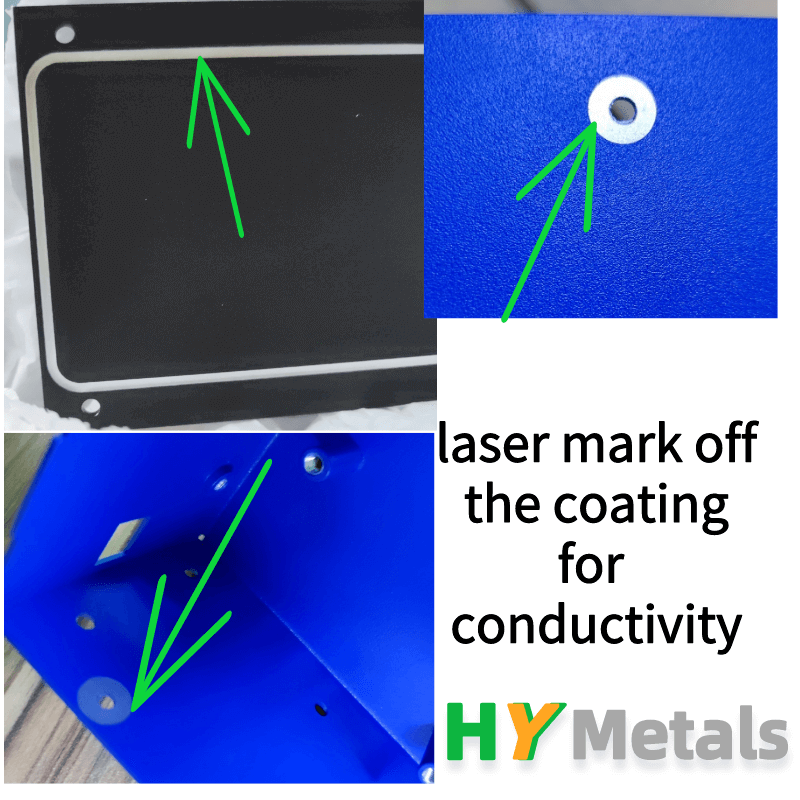

Ipeyinti yokumakisha iLaser

Nayiphi na imveliso enokuthi iphawulwe ngelaser inika iingenelo ezibalulekileyo xa iqatywe. Ukumakishwa kweLaser yeyona ndlela ibalaseleyo yokususa iingubo ngexesha lendibano, rhoqo emva kweendawo zokugquma. Le ndlela yokumakisha ishiya umfanekiso owenziwe mnyama kwindawo yentsimbi ekhangeleka kakuhle kwaye ihluke kunye nommandla ojikelezayo.

Isishwankathelo, i-mask ibalulekile xa ugubungela iindawo zetsimbi eziqhelekileyo ezingenazo iimfuno zokugquma kwiindawo ezichongiweyo. Nokuba usebenzisa i-anodizing, i-electroplating okanye i-powder coating, iimveliso ezahlukeneyo zifuna iindlela ezizodwa zokufihla ukuze kuqinisekiswe umgangatho wemveliso yokugqibela. Qiniseka ukuba uthatha imiqathango yokukhusela ngononophelo phambi kokuba uqhubeke nenkqubo yokugquma.