Ukugoba kwecwecwe yinkqubo eqhelekileyo yokuvelisa esetyenziselwa ukwenza amacandelo ahlukeneyo kunye neemveliso. Inkqubo ibandakanya ukuguqulwa kwephepha lesinyithi ngokufaka amandla kulo, ngokuqhelekileyo kusetyenziswa i-press brake okanye umatshini ofanayo. Oku kulandelayo sisishwankathelo senkqubo yokugoba yamaphepha esinyithi:

1. Ukukhetha izinto eziphathekayo: Inyathelo lokuqala kwiukugoba ishidi lentsimbiinkqubo kukukhetha imathiriyeli efanelekileyo. Izinto eziqhelekileyo ezisetyenziselwa ukugoba i-sheet metal zibandakanya intsimbi, i-aluminium kunye nensimbi engenasici. Ubuninzi bephepha lesinyithi buya kuba yinto ephambili ekunqumeni inkqubo yokugoba. Kwi-HY Metals, sisebenzisa izinto ezichazwe ngabathengi.

2. Ukukhethwa kwesixhobo:Isinyathelo esilandelayo kukukhetha isixhobo esifanelekileyo somsebenzi wokugoba. Ukukhethwa kwesixhobo kuxhomekeke kwizinto eziphathekayo, ubukhulu kunye nobunzima be-bend.

Ukukhetha isixhobo sokugoba esifanelekileyo kubalulekile ekufezekiseni ukugoba okuchanekileyo kunye nomgangatho ophezulu ngexesha lenkqubo yokugoba isinyithi. Nazi ezinye izinto ezibalulekileyo xa ukhetha isixhobo sokugoba:

2.1 Uhlobo lwezinto eziphathekayo kunye nobukhulu:Uhlobo lwezinto eziphathekayo kunye nobukhulu beplate luya kuchaphazela ukukhethwa kwezixhobo zokugoba. Izixhobo eziqinileyo njengentsimbi engatyiwayo zinokufuna izixhobo ezomeleleyo, ngelixa izinto ezithambileyo njengealuminiyam zinokufuna ukuqwalaselwa kwezixhobo ezahlukeneyo. Izixhobo ezityebileyo zinokufuna izixhobo ezomeleleyo ukumelana namandla okugoba.

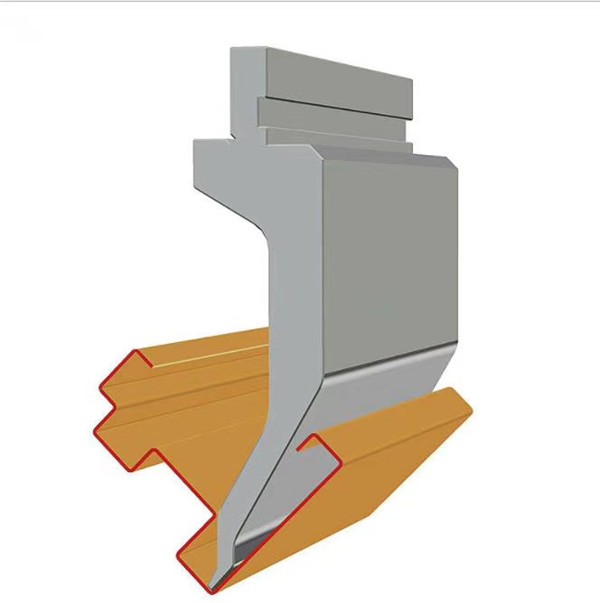

2.2 i-engile yokugoba kunye neRadiyosi:I-angle yokugoba efunekayo kunye ne-radius iya kugqiba uhlobo lwesixhobo esifunekayo. Ukufa okungafaniyo kunye ne-punch indibaniselwano isetyenziselwa ukufikelela kwii-engile zokugoba ezithile kunye ne-radii. Ukugoba okuqinileyo, i-punches encinci kunye nokufa kunokufuneka, ngelixa i-radii enkulu ifuna izicwangciso zezixhobo ezahlukeneyo.

2.3 Ukuhambelana kwesixhobo:Qinisekisa ukuba isixhobo sokugoba osikhethayo siyahambelana nebrake yokucofa okanye umatshini wokugoba osetyenziswayo. Izixhobo kufuneka zibe ubukhulu obufanelekileyo kunye nohlobo lomatshini othile ukuqinisekisa ukusebenza okufanelekileyo kunye nokhuseleko.

2.4 Izixhobo zokusebenza:Qwalasela izixhobo zokugoba izixhobo. Izixhobo eziqinileyo kunye neziphantsi zihlala zisetyenziselwa ukugoba ngokuchanekileyo kunye nokumelana namandla abandakanyekayo kwinkqubo. Izixhobo zesixhobo zinokubandakanya insimbi yesixhobo, i-carbide, okanye ezinye ii-alloys eziqinisiweyo.

2.5 IiMfuno eziZodwa:Ukuba inxalenye egobileyo ineempawu ezikhethekileyo, ezifana ne-flanges, i-curls, okanye i-offsets, izixhobo ezikhethekileyo zingafuneka ukufezekisa ngokuchanekileyo ezi mpawu.

2.6 Ukugcinwa komngundo kunye nexesha lokuphila:Qwalasela iimfuno zogcino kunye nobomi beukugoba ngundo. Izixhobo ezisemgangathweni zinokuhlala ixesha elide kwaye zitshintshwe rhoqo, ukunciphisa ixesha lokunciphisa kunye neendleko.

2.7 Izixhobo zesiNtu:Kwiimfuno ezizodwa okanye ezintsonkothileyo zokugoba, izixhobo zesiko zinokufuneka. Izixhobo eziqhelekileyo zinokuthi ziyilwe kwaye zenziwe ukuhlangabezana neemfuno ezithile zokugoba.

Xa ukhetha isixhobo sokugoba, kubalulekile ukubonisana nomthengisi wesixhobo onamava okanye umenzi wokuqinisekisa ukuba isixhobo esikhethiweyo sifanelekile kwisicelo esithile sokugoba kunye nomatshini. Ukongeza, ukuqwalasela izinto ezinje ngeendleko zesixhobo, ixesha lokukhokela, kunye nenkxaso yababoneleli kunokunceda ukwenza isigqibo esinolwazi.

3. Seta: Nje ukuba izinto kunye nokungunda zikhethiwe, ukuseta i-brake yokushicilela kubalulekile. Oku kubandakanya ukulungiswa kwe-backgauge, ukunyanzelisa i-sheet metal endaweni, kunye nokuseta iiparamitha ezichanekileyo kwi-brake yokushicilela, njenge-angle yokugoba kunye nobude be-bend.

4. Inkqubo yokugoba:Nje ukuba ukuseta kugqityiwe, inkqubo yokugoba inokuqalisa. Isiqhoboshi socinezelo sisebenzisa amandla kwiphepha lesinyithi, libangela ukuba likhubaze kwaye ligobe kwi-engile oyifunayo. Umsebenzisi kufuneka abeke iliso ngokucokisekileyo inkqubo yokuqinisekisa i-angle echanekileyo yokugoba kunye nokuthintela naziphi na iziphene okanye umonakalo wezinto eziphathekayo.

5. Ulawulo lomgangatho:Emva kokuba inkqubo yokugoba igqityiwe, khangela ukuchaneka kunye nomgangatho weplate yensimbi egobileyo. Oku kunokubandakanya ukusebenzisa izixhobo zokulinganisa ukuqinisekisa ii-engile ezigobileyo kunye nemilinganiselo, kunye nokuhlola okubonakalayo naziphi na iziphene okanye ukungafezeki.

6. Imisebenzi yasemva kokugoba:Ngokuxhomekeke kwiimfuno ezithile zenxalenye, imisebenzi eyongezelelweyo efana nokulungisa, ukubetha, okanye i-welding inokwenziwa emva kwenkqubo yokugoba.

Kuko konke,ukugoba ishidi lentsimbiyinkqubo esisiseko kwimveliso yesinyithi kwaye isetyenziselwa ukudala iintlobo ezahlukeneyo zeemveliso, ukusuka kwizibiyeli ezilula ukuya kwizindlu ezintsonkothileyo kunye neenxalenye zesakhiwo. Inkqubo ifuna ingqalelo ekhethekileyo ekukhethweni kwezinto, izixhobo, ukuseta, kunye nokulawula umgangatho wokuqinisekisa ukugoba okuchanekileyo kunye nomgangatho ophezulu.

Ixesha lokuposa: Jul-16-2024