Kukho izakhiwo ezikhethekileyo okanye iimpawu ezicela umngeni ukuziqulunqaiprototype yentsimbiamalungu:

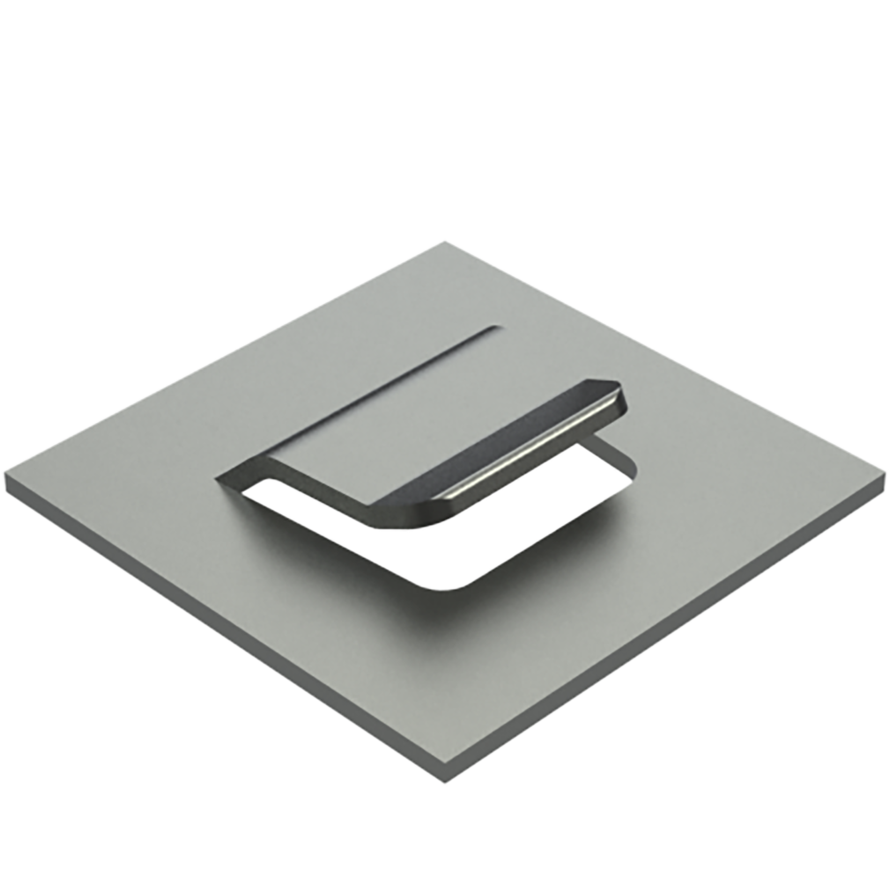

1.ILance (刺破)

In ukwenziwa kwamaphepha esinyithi, Umkhonto ngumsebenzi owenza amancinci, amanxeba amancinci okanye amaqhekeza kwiphepha lesinyithi. Le cutout yenzelwe ngononophelo ukuvumela isinyithi ukugoba okanye ukugoba kwimigca yokusikwa. I-Lance isoloko isetyenziselwa ukuququzelela ukugoba kunye nokwenza iimilo ezinzima kunye nezakhiwo kwiindawo zentsimbi.

Nazi ezinye iinkcukacha eziphambili kunye nokuqwalaselwa malunga nokusetyenziswaumkhonto kulwakhiwo lwentsimbi:

Injongo:Umkhonto usetyenziselwa ukwenza imigca yokugoba esele imiselwe kumaphepha esinyithi, ngaloo ndlela kuphunyezwa imisebenzi yokugoba echanekileyo nelawulwayo. Ziluncedo ngakumbiukwenza iifins, iiflange, kunye nezinye iimpawu ezifuna ukugoba okubukhali okanye iijometri ezintsonkothileyo.

Iingqwalasela zoyilo:Xa udibanisa iLance kuyilo lwenxalenye yentsimbi yeshidi, kubalulekile ukuqwalasela ubukhulu bezinto eziphathekayo, i-angle kunye nobude be-lance, kunye nokunyaniseka kwesakhiwo senxalenye. Umkhonto oyilwe ngokufanelekileyo unceda ukunciphisa ukugqwetheka nokuqinisekisa ukugoba okuchanekileyo.

Inkqubo yokugoba:Umkhonto udla ngokusetyenziswa ngokubambisana nomatshini wokugoba okanye ezinye izixhobo zokwenza ukugoba ipleyiti yentsimbi ecaleni komgca wokusika. Umkhonto unika indawo ecacileyo yokugoba ukwenzela ukubumba okungaguquguqukiyo nokuphindaphindwayo.

Ukuguqulwa kwezinto:Ngexesha leukugobainkqubo, ingqalelo ngenyameko kufuneka ihlawulwe ukuba kunokwenzeka deformation izinto okanye ukuqhekeka kufutshane cutout ilance. Izixhobo ezifanelekileyo kunye neendlela zokugoba zibalulekile ekunciphiseni ezi ngxaki.

Isicelo: I-Lance idla ngokusetyenziselwa ukwenzaizindlu, izibiyeli,amacandelo e-chassiskunye namanye amacandelo esinyithi afuna iijiyometri ezichanekileyo nezintsonkothileyo.

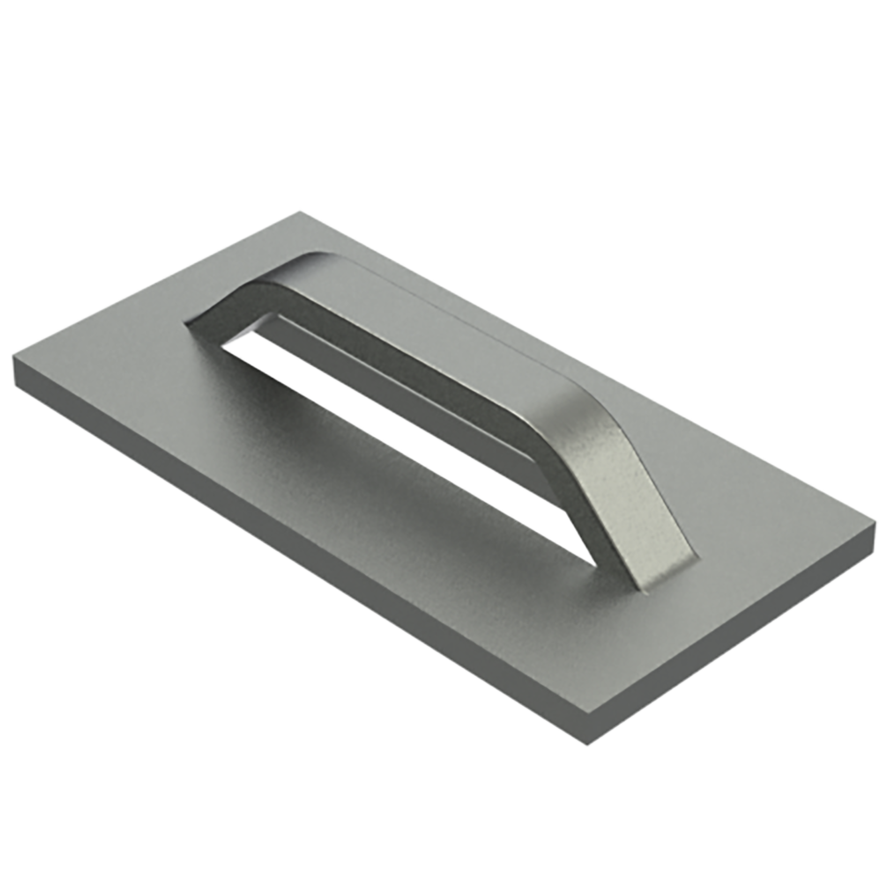

2.Ibhulorho (线桥)

In ishidi lentsimbi, iibhulorhoziphakanyiswe izahlulo zemathiriyeli, edla ngokusetyenziswa ukwenza iindlela zokuwela iintambo okanye iingcingo. Olu phawu luqhele ukufunyanwa kwiiindawo ezivaliweyo ze-elektroniki, iiphaneli zokulawula, kunye nezinye izixhobo ezifuna iingcingo nge sheet sheet.

Ibhuloho yenzelwe ukubonelela ngendlela elungelelanisiweyo kunye nekhuselweyo kwiintambo, ukuthintela ukuba zifakwe, zonakaliswe okanye zidibanise. Kwakhona kunceda ukugcina inkangeleko ecocekileyo kunye neyobuchule kwindibano yonke.

Xa uyila iibhulorho zentambo kumacandelo esinyithi, izinto ezininzi kufuneka ziqwalaselwe:

Ubungakanani kunye nokumila:Ibhulorho kufuneka ilungiselelwe ukulungiselela ubungakanani kunye nenani leentambo ekufuneka zidlule kuyo. Kufuneka kubekho indawo evulekileyo eyaneleyo yokuthintela ukuxinana kunye nokuququzelela ukufakela nokugcinwa kwentambo.

Imiphetho egudileyo:Amaphethelo etreyi yekhebula kufuneka agudileyo ngaphandle kwama-burrs abukhali okanye arhabaxaimiphezulu yokuthintela umonakalo wentambo xa udlula.

Ukunyuswa kunye neNkxaso:Ibhuloho kufuneka ifakwe ngokukhuselekileyo kwiphepha lesinyithi kwaye inike inkxaso eyaneleyo yeentambo. Oku kunokubandakanya izibiyeli ezongezelelweyo okanye izixhaso zokuqinisekisa ukuzinza kwebhulorho.

I-EMI/RFI iyakhusela:Kwezinye iimeko, ibhulorho inokufuna ukubonelela ngokuphazamiseka kwe-electromagnetic (EMI) okanye ukuphazanyiswa kwerediyo yerediyo (RFI) ukukhusela intambo ekuphazamisekeni kwangaphandle.

Ukufikeleleka:Uyilo lwebhulorho kufuneka luvumele ukufikelela lula kwiintambo zokugcinwa okanye ukutshintshwa ngaphandle kokuqhawula yonke indibano yentsimbi yeshiti.

Ngokuqwalasela ngokucophelela le miba, iibhulorho zekhebula kwiingxenye zentsimbi zinokuthi zenzelwe ngokufanelekileyo ukubonelela ngendlela ethembekileyo nelungelelanisiweyo yeentambo, ngaloo ndlela inceda ukuphucula ukusebenza ngokubanzi kunye nokuqina kwendibano.

3.Ukuhombisakunye neRibs(凸包和加强筋)

I-embossing ibandakanya ukudala idizayini ephakanyisiweyo okanye iphethini phezu kwephepha lesinyithi. Kunokuba ngumceli mngeni ukufezekisa ukuhambelana kunye nokufaka i-embossing ngaphandle kokubangela i-deformation okanye i-warping yeendawo ezikufutshane.

I-embossing kunye neembambo zizinto ezimbini ezibalulekileyo kwi-sheet metal form forming ezisetyenziselwa ukunyusa ukunyaniseka kwesakhiwo, i-aesthetics, kunye nokusebenza kwenxalenye yokugqibela.. Nalu ushwankathelo lwento nganye:

Embossing (凸包):

I-embossing ibandakanya ukudala idizayini ephakanyisiweyo okanye iphethini kumphezulu wephepha lesinyithi. Oku kunokwenziwa ngeenjongo zokuhombisa, ukubonisa iilogo okanye umbhalo, okanye ukongeza ukuthungwa kwindawo.

Ukongeza kwi-aesthetics, i-embossing ingasetyenziselwa ukuqinisa imimandla ethile yecandelo lentsimbi yeshidi, inika amandla okongeziweyo kunye nokuqina.

Inkqubo yokufaka i-embossing ibandakanya ukusetyenziswa kwesixhobo esikhethekileyo kwaye iyafa ukucinezela ipateni efunekayo okanye uyilo kwishiti lesinyithi.

Iimbambo(加强筋):

Iimbambo zidla ngokusetyenziselwa ukuqinisa iipaneli zentsimbi ezisicaba okanye ezigobileyo, ezithintela ukuba zingabhibhi okanye zigqwetheke phantsi komthwalo.

Ngokucwangcisa ngokucwangcisa iimbambo kuyilo, ubunzima obupheleleyo benxalenye bunokuncitshiswa ngelixa kugcinwa ukuthembeka kwesakhiwo.

Ukongezwa kweembambo nako kunokuphucula ukuxhathisa kwenxalenye ukugoba, ukugoba, kunye nezinye iindlela zoxinzelelo lomatshini.

Zomibini i-embossing kunye neembambo zindlela ezibalulekileyo kwi-sheet metal forming forming, ezivumela abavelisi ukuba benze iinxalenye ezingabonakali nje ngokubonakalayo kodwa kunye nesakhiwo esinamandla kunye nokusebenza. Ezi mpawu zihlala zibandakanyiwe kuluhlu olubanzi lweemveliso, kubandakanywa amacandelo emoto, i-electronic enclosures, iiphaneli zezixhobo, kunye neempahla ezahlukeneyo zabathengi.

4.Louvers (百叶风口)

Ii-louvers luhlobo lwenkqubo yokungenisa umoya edla ngokusetyenziswa kwi- sheet metal fabrication.Ziyilelwe ukuvumela umoya ukuba ugqithe ngelixa zithintela ukungena kwamanzi, ukungcola, okanye enye inkunkuma. Ii-Louvers zenziwa ngokusika okanye ukugqobhoza uthotho lwee-slits okanye imingxuma kwiphepha lesinyithi, kwaye emva koko ukugoba isinyithi ukwenza uthotho lwamaphiko aneengile okanye iincakuba.

Ii-Louvers zinokusetyenziswa kwizicelo ezahlukeneyo, kubandakanya iinkqubo ze-HVAC, izixhobo zemizi-mveliso, izinto zemoto, kunye neempawu zoyilo. Zihlala zisetyenziselwa ukuphucula ukuhamba komoya kunye nokungena komoya kwizakhiwo, oomatshini, kunye nezithuthi, kunye nokubonelela ngobuhle.

Kukwenziwa kwamaphepha entsimbi, iilouvers zenziwa kusetyenziswa izixhobo ezikhethekileyo ezinje ngoomatshini bokushicilela be-punch, oomatshini bokusika i-laser, okanye iirutha ze-CNC. Uyilo kunye nokubekwa kweelouvers kubalwa ngononophelo ukuqinisekisa ukuhamba komoya kunye nokusebenza.

Ii-louvers zingenziwa kwizinto ezahlukeneyo, kuquka i-aluminium, intsimbi, insimbi engenasici, kunye nobhedu, kuxhomekeke kwiimfuno ezithile zesicelo. Zisenokugqunywa okanye zipeyintwe ukunika ukhuseleko olongezelelweyo ekudlekeni kunye nokuhambelana nobuhle bemekobume engqongileyo.

Ngokubanzi, ii-louvers ziyingxenye ebalulekileyo kwi-sheet metal fabrication, ukubonelela zombini izibonelelo ezisebenzayo kunye ne-aesthetic kuluhlu olubanzi lwezicelo.

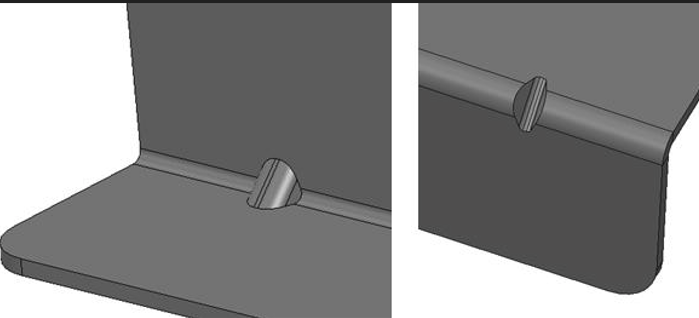

5.Lugskunye neeNotshi(凸耳,切槽)

I-Lugs kunye neenotshi zi-protrusions ezincinci okanye ukusika kwiipleyiti zetsimbi ezisetyenziselwa ukudibanisa okanye ukuxhamla. Kunokuba ngumngeni ukwenza iithebhu kunye neenotshi ezihambelana ngokuchanekileyo nangokukhuselekileyo ngaphandle kokubangela ulungelelwaniso lwenxalenye okanye amanqaku abuthathaka.

Kwi-sheet metal fabrication, iilugs kunye neenotshi ziimpawu ezisetyenziswa ngokuqhelekileyo ezisebenzela iinjongo ezahlukeneyo kuyilo kunye nokusebenza kwemveliso yokugqibela.

Lugs:

I-Lugs luqikelelo oluncinci okanye izandiso kwiqhekeza lesinyithi elidla ngokusetyenziselwa ukuncamathelisa okanye ukukhusela amanye amacandelo. Zihlala zisetyenziselwa iinjongo zokuxhoma, ezifana nokuncamathisela izibiyeli, iziqhoboshi, okanye ezinye iindawo kwiphepha lesinyithi. I-Lugs inokudalwa ngeenkqubo ezinjengokubhobhoza, ukugrumba, okanye ukusika i-laser, kwaye zihlala zigobile okanye zenziwe ngendlela efunwayo ukuze zinike indawo yokuncamathela ekhuselekileyo. I-Lugs ibalulekile ekuqinisekiseni imfezeko yesakhiwo kunye nokuzinza kwendibano yokugqibela.

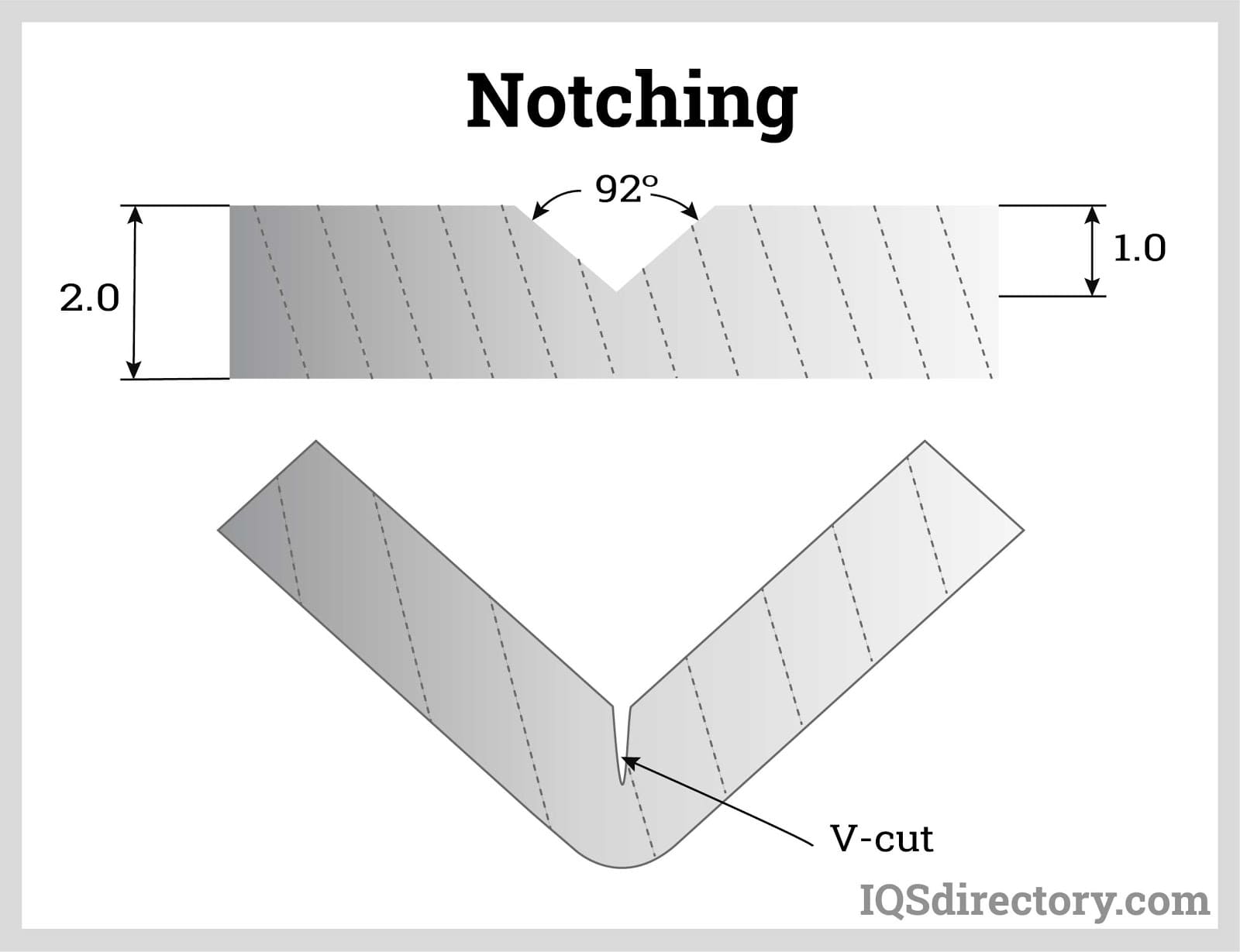

Iinotshi:

Iinotshi kukungena okanye ukusika kwishiti lesinyithi elisebenza ngeenjongo ezahlukeneyo, ezinjengokufaka amanye amacandelo, ukubonelela ngokucocwa kweziqhoboshi, okanye ukuvumela ukugotywa okanye ukwenza isinyithi. Iinotshi zinokwenziwa kusetyenziswa iinkqubo ezinje ngokusika i-laser, ukucheba, okanye ukugqobhoza, kwaye zihlala ziyilelwe ukuchaneka imilinganiselo yokuqinisekisa ukufaneleka nokusebenza ngokufanelekileyo. Iinotshi zibalulekile ekwenzeni i-sheet metal ukuba ingene kwiindibano, ilungelelaniswe namanye amacandelo, okanye iququzelele ukugoba kunye nokubunjwa kwesinyithi ngaphandle kokubeka esichengeni isidima sayo solwakhiwo.

Zombini iilugi kunye neenotshi zizinto ezibaluleke kakhulu kulwakhiwo lwentsimbi, kwaye zifuna ukuqwalaselwa ngononophelo kuyilo kunye nenkqubo yokuvelisa ukuqinisekisa ukuba ziyahlangabezana neemfuno ezithile zemveliso yokugqibela. Ezi mpawu zidlala indima ebalulekileyo ekusebenzeni ngokubanzi, ukudibanisa, kunye nokusebenza kwamacandelo esinyithi kunye neendibano.

Zonke ezi mpawu zikhethekileyo zingumngeni kwi-sheet metal fabrication ngokukodwa kwinkqubo yeprototyping yesinyithi ngaphandle kokwenza izixhobo. Bafuna ukuqwalaselwa ngononophelo kunye nobuchule kwiprototyping yesinyithi ukuqinisekisa ukuba zenziwa ngokuchanekileyo nangempumelelo. I-HY Metals apha ziingcali kuzo zonke ezo zakhiwo zinzima kunye neempawu. Senze iindawo ezininzi ezigqibeleleyo ezineempawu ezinjalo.

Ixesha lokuposa: Mar-22-2024