Amalungu e-aluminiyam anodizinglunyango oluqhelekileyo lomphezulu olonyusa ukuxhathisa kwabo ekudlekeni, ukuqina, kunye nobuhle.Kwiphepha lethu lesinyithi kunye ne-CNC yokwenza ukuveliswa komatshini, kukho iindawo ezininzi ze-aluminiyam ekufuneka zifakwe i-anodized, zombiniAluminiyam sheet metal amalungukwayeAluminiyam CNC iinxalenye ngomatshini. Kwaye ngamanye amaxesha umthengi ufuna iindawo ezigqityiweyo zigqibeleleyo ngaphandle kweziphene. Abakwazi ukwamkela iindawo zoqhagamshelwano ezicacileyo ezicacileyo apho kungabikho ukutyabeka kwe-anodizing.

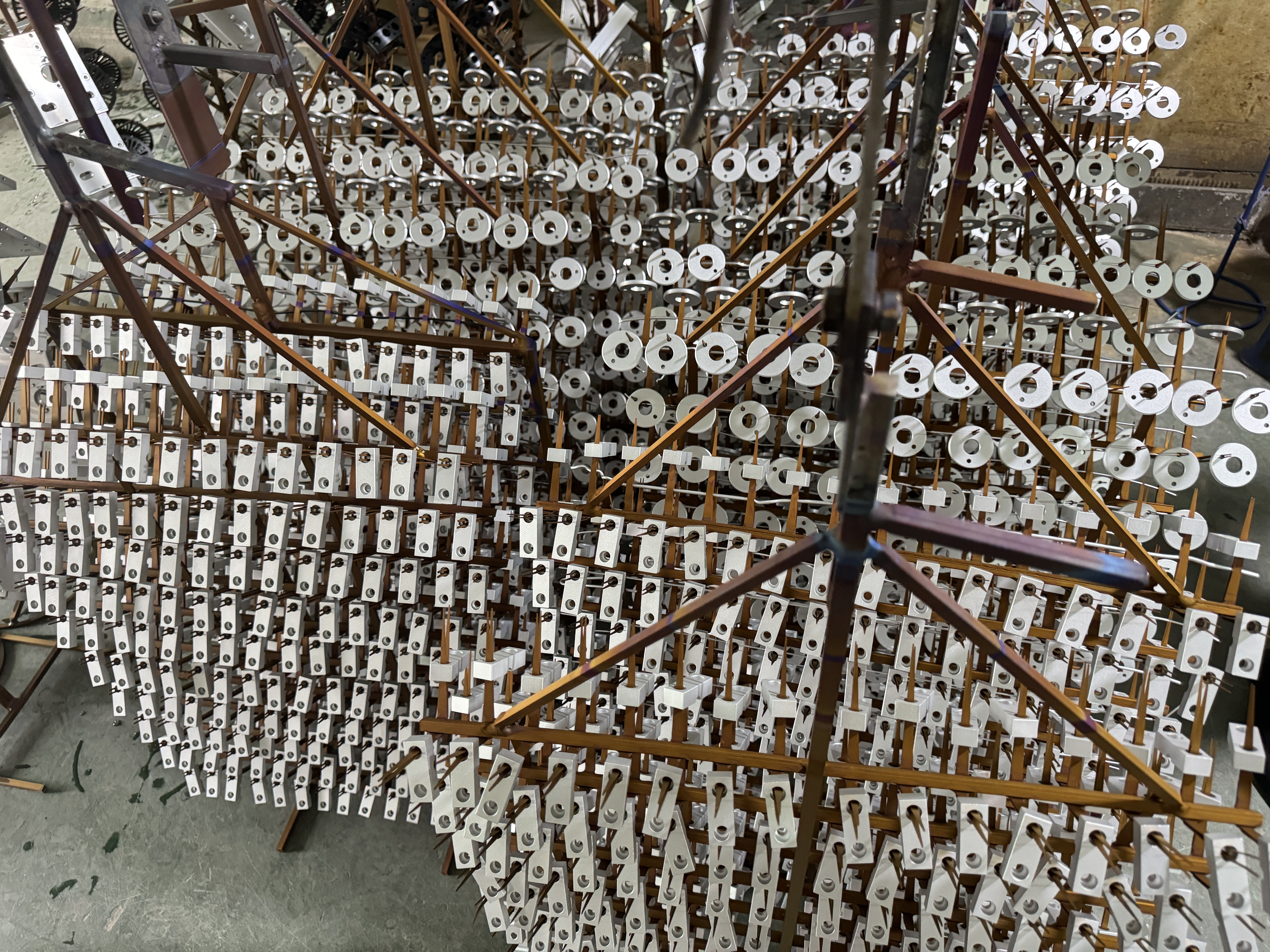

Nangona kunjalo, ngexesha lokukhulelwaaluminiyam anodizinginkqubo, iindawo zoqhagamshelwano okanye iindawo apho inxalenye idibana ngokuthe ngqo kunye ne-bracket yokulenga okanye i-shelf ayikwazi ukukhutshwa ngokufanelekileyo ngenxa yokungabikho kokufikelela kwisisombululo se-anodizing. Lo mda uvela kubume benkqubo ye-anodizing kunye nesidingo soqhagamshelwano olungenakuthintelwa phakathi kwenxalenye kunye nesisombululo se-anodizing ukuphumeza ukugqiba okufanayo kunye nokuhambelana komphezulu we-anodized.

Iinkqubo anodizingkubandakanya ukucwiliswa kweengxenye ze-aluminium kwisisombululo se-electrolyte kunye nokugqithiswa kombane ngokusebenzisa isisombululo, ukudala i-oxide layer kwi-aluminium surface. Lo maleko oxide ubonelela ngeenzuzo ezizodwaaluminiyam anodized, okufana nokomelezwa kokumelana nomhlwa, ukuphucuka kokuqina, kunye nokukwazi ukwamkela umbala wedayi.

Nangona kunjalo, xa iinxalenye ze-anodized zisebenzisa i-bracket ejingayo okanye i-rack, iindawo zoqhagamshelwano apho inxalenye idibana ngokuthe ngqo nesibiyeli ikhuselwe kwisisombululo se-anodizing.. Ngoko ke, ezi ndawo zoqhagamshelwano azihambi kwinkqubo ye-anodizing njengenxalenye yonke, okukhokelela kwiindawo zokuxhoma okanye amanqaku emva kwe-anodization.

Ukusombulula le ngxaki kunye nokunciphisa ukubonakala kwamanqaku okunqunyanyiswa, kufuneka kuqwalaselwe ngokucophelela ukuyila kunye nokubekwa kwezibiyeli zokumisa kunye nobuchule bokugqiba emva kwe-anodizing.Ukukhetha izibiyeli zokumisa kunye nommandla omncinci kunye nokubekwa kweqhinga kunokuncedisa ukunciphisa impembelelo yamanqaku oqhagamshelwano ekubonakaleni kokugqibela kwenxalenye ye-anodized. Ukongezelela, iinkqubo ze-post-anodization ezifana ne-sanding light, polishing, okanye ukuguqulwa kwe-anodizing yendawo ingasetyenziselwa ukunciphisa ukubonakala kwamanqaku okuxhoma kunye nokufezekisa ukugqitywa kwe-anodized surface.

Isizathu sokuba iingongoma zoqhagamshelwano zingenako i-anodized ngexesha lenkqubo ye-aluminium anodizing ngenxa yesithintelo somzimba esibangelwa i-bracket yokuxhoma okanye i-shelf. Ngokuphumeza uyilo olucingisisiweyo kunye nezicwangciso zokugqiba, abavelisi banokunciphisa impembelelo yamanqaku oqhagamshelwano kumgangatho jikelele kunye nokubonakala kweengxenye ze-aluminium anodized.

Injongo yeli nqaku kukuhlola ukukhethwa kwezibiyeli zokunqunyanyiswa kwe-anodized, izicwangciso zokunciphisa iindawo zokuxhoma, kunye nobuchule bokuqinisekisa umgangatho ogqibeleleyo we-anodized.

Khetha isibiyeli sokunqunyanyiswa esifanelekileyo:

Xa ukhetha isibiyeli sokunqunyanyiswa kwe-anodized, kubalulekile ukuqwalasela ezi zinto zilandelayo:

1. Ukuhambelana kwezinto: Qinisekisa ukuba i-bracket yokumiswa yenziwe kwizinto eziphathekayo ezihambelana nenkqubo ye-anodizing, njenge-titanium okanye i-aluminium. Oku kuthintela naziphi na iziphumo ezibi ezinokuchaphazela umgangatho we-anodized surface.

2. Uyilo kunye neJometri:Uyilo lwe-bracket yokumiswa lukhethwa ukunciphisa amanqaku oqhagamshelwano kunye nenxalenye yokunciphisa umngcipheko wokushiya amanqaku abonakalayo. Qwalasela ukusebenzisa izibiyeli ezinencam ezigudileyo, ezingqukuva kunye nendawo encinci yomphezulu ukudibana nenxalenye.

3. Ukumelana nobushushu:I-Anodizing ibandakanya amaqondo obushushu aphezulu, ngoko ke isibiyeli sokunqunyanyiswa kufuneka sikwazi ukumelana nobushushu ngaphandle kokujija okanye ukonakala.

Nciphisa iindawo zokuxhoma:

Ukunciphisa ukwenzeka kwamabala okuxhoma kwiindawo ezine-anodized aluminiyam, ezi ndlela zilandelayo zingasetyenziswa:

1. Ukubekwa ngobuchule: Beka ngononophelo izibiyeli zokunqunyanyiswa kwicala ukuze uqinisekise ukuba nawaphi na amanqaku avelisiweyo akwiindawo ezingabonakaliyo okanye anokufihlwa ngokulula ngexesha lokudityaniswa okulandelayo okanye iinkqubo zokugqiba. Kwaye kufuneka ulumke xa uthatha amalungu kwizibiyeli ukukhusela iindawo ezingaphezulu.

2. Ukugquma ubuso: Sebenzisa ubuchule bokugquma okanye ukukhusela iindawo ezibalulekileyo okanye iindawo apho iindawo zokuxhoma zinokuthi zenzeke. Oku kunokubandakanya ukusebenzisa iiteyiphu ezikhethekileyo, iiplagi okanye iicoatings ukukhusela iindawo ezithile ekudibaneni nesibiyeli sokunqunyanyiswa.

3. Ukulungiswa komphezulu: Phambi kwe-anodizing, cinga ukusebenzisa unyango olungaphezulu okanye unyango lomphezulu ukunceda ukufihla okanye ukudibanisa naziphi na iindawo ezishiyekileyo zokuxhoma kwinkangeleko epheleleyo yecandelo.

Qinisekisa ukugqitywa okugqibeleleyo kwe-anodized:

Emva kwe-anodizing, inxalenye kufuneka ihlolwe ukuba kukho naziphi na iindawo eziseleyo zokunqunyanyiswa kunye nesenzo sokulungisa njengoko kuyimfuneko. Oku kunokubandakanya ubuchule basemva kokulungiswa okufana nesanti ekhanyayo, ukupholisha okanye ukulungiswa kwe-anodizing yendawo ukuze kupheliswe okanye kuncitshiswe ukubonakala kwazo nakuphi na ukungafezeki.

Isishwankathelo, ukufikelela kwisiphelo se-anodized esingenamthungo kumalungu e-aluminium anezibiyeli ezisisigxina kufuna ingqalelo ecokisekileyo yokukhethwa kwesibiyeli, ukubekwa kobuchule, kunye nokuhlolwa kwe-post-anodization kunye neenkqubo zokucokisa. Ngokuphumeza ezi zenzo, abavelisi banokunciphisa ubukho beendawo zokuxhoma kwaye baqinisekise ukuba iinxalenye ze-anodized zihlangabezana nomgangatho ophezulu kunye nemigangatho yobuhle.

Ixesha lokuposa: May-20-2024