Imveliso yazisa

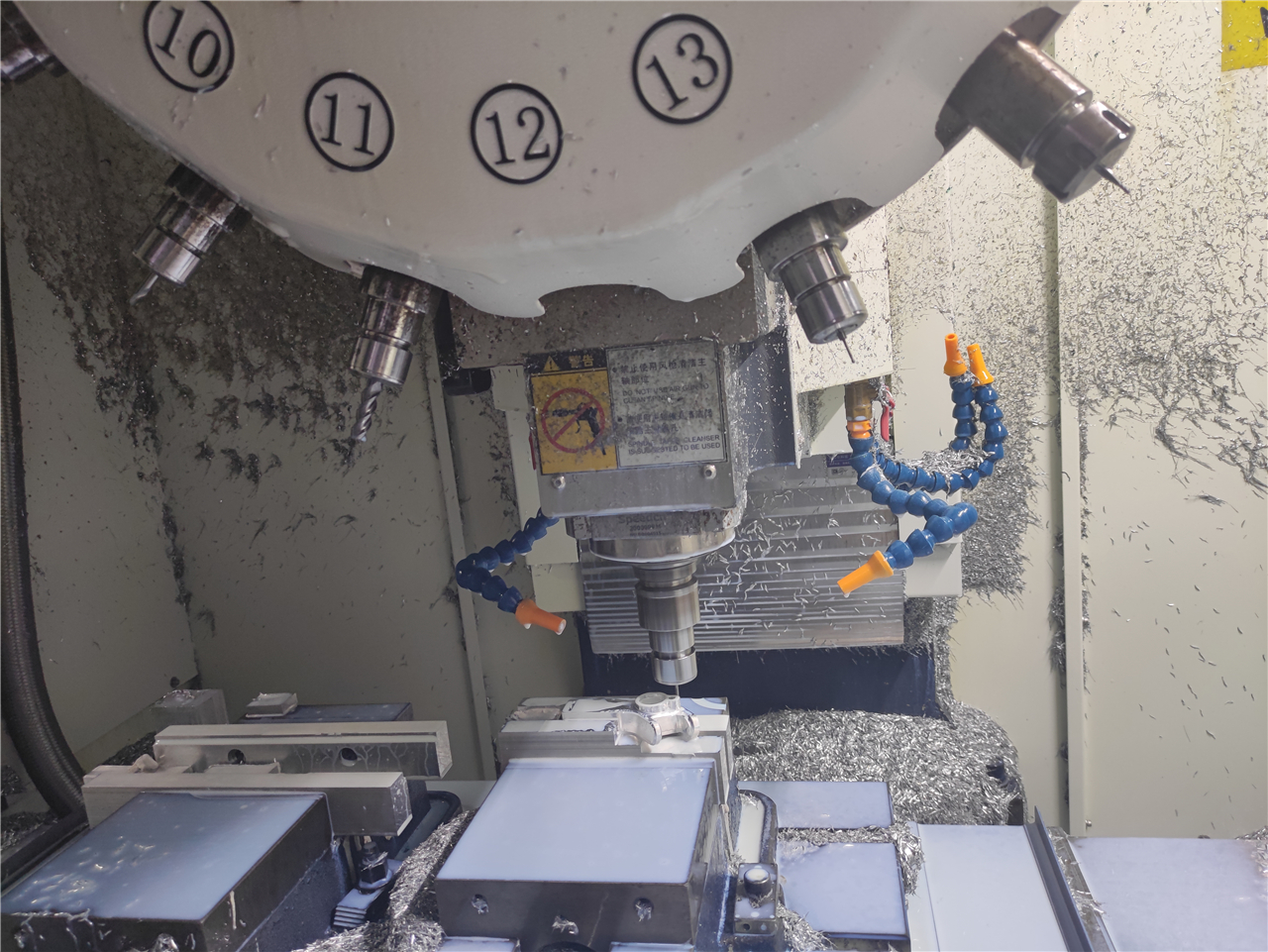

Kwimeko yemveliso yanamhlanje ekhawulezayo, kukho imfuno ekhulayo yengokukhawuleza, iindawo ezichanekileyo zomatshini we-CNC. Le nkqubo yokuvelisa ibonelela ngokuchaneka okungenakuthelekiswa nanto, ukusebenza kakuhle kunye nokungaguquguquki, okwenza ukuba ilungele amashishini ahlukeneyo kuqukai-aerospace, iimotokwayeezonyango.

Nangona kunjalo, inkqubo yokuvelisa la macandelo anzima ayinayo imingeni.

Kweli nqaku, siza kuphonononga ubunzima ekuhlangabezene nabo kunye namanqaku ekufuneka siqwalaselwe xa kuveliswaukuchaneka ngokukhawuleza CNC iinxalenye ngomatshini.

1.Ukuntsokotha nokuqwalaselwa koyilo

Uyilo oluntsonkothileyo ludlala indima ebalulekileyo ekuvelisweni kweendawo ezichanekileyo zomatshini weCNC. Iijometri ezintsonkothileyo, ukunyamezelana okuqinileyo kunye neentshukumo ezininzi ze-axis zifuna ukucwangciswa ngononophelo kunye nobuchule. Ukuqinisekisa ukuba uyilo lulungiselelwe ukwenziwa kwezinto ukusuka kumanqanaba okuqala kubalulekile.

Intsebenziswano phakathi kweenjineli zoyilo kunye nabadwelisi benkqubo be-CNC inceda ukuchonga imingeni yoyilo enokubakho kwangoko, ukulungelelanisa iinkqubo zomatshini kunye nokunciphisa ukulibaziseka okunokwenzeka.

2.Ukukhetha izinto eziphathekayo

Enye into ephambili ekufuneka iqwalaselwe yileukhetho lwezinto eziphathekayo. Izixhobo ezahlukeneyo zizisa imingeni eyahlukeneyo yokucwangcisa, kwaye ukukhetha izinto ezifanelekileyo kwisicelo esifunekayo kubalulekile. Izinto ezithile, ezifana ne-alloys enganyangekiyo ubushushu okanye isinyithi esinqabileyo, kunzima ukwenza umatshini ngenxa yobunzima kunye ne-ductility. Ukuphonononga ukuchaneka kwesixhobo, ukuhanjiswa kwe-thermal kunye nokuqina kweempawu kubalulekile ukunqanda ukunxitywa kwesixhobo, imiba yokugqiba umphezulu okanye ukusilela ngexesha lomatshini.

3.Ubuchule bomatshini kunye nokucwangcisa

Ukukhawuleza, ukuchaneka komatshini we-CNC wamacandelo kuxhomekeke kakhulu kwizakhono zomatshini we-CNC osetyenziswayo. Ukuchaneka komatshini, ukuphindaphinda kunye nesantya se-spindle kuchaphazela kakhulu umgangatho wemveliso yokugqibela.

Ukongeza, kubalulekile ukubaabadwelisi benkqubo beCNC abanezakhono nabanamavangubani onokunyusela iindlela zesixhobo, khetha iiparamitha zokusika ezifanelekileyo, kunye nemisebenzi yobutshixo entsonkothileyo yenkqubo.

4.Ukukhethwa kwesixhobo kunye nokulungiswa kwendlela yesixhobo

Ukukhetha isixhobo esifanelekileyo sokusika kubalulekile ekufezekiseni ukuchaneka komatshini we-CNC. Izixhobo zesixhobo, i-geometry yesixhobo, iingubo, njl.njl kufuneka ziqwalaselwe ngokusekelwe kwizinto ezenziwa ngoomatshini kunye nokuphela komhlaba ofunekayo kunye nokunyamezela.

Ukongeza, kubalulekile ukwenza iindlela zesixhobo ukunciphisa ixesha lokusika, ukunciphisa ukunxiba kwesixhobo, kunye nokuqinisekisa umgangatho ongaguqukiyo kwiindawo ezininzi. Ukusebenzisa isoftware yeCAM ephucukileyo kunokunceda ukuvelisa iindlela zesixhobo eziphuculweyo zokuqinisekisa inkqubo esebenzayo yomatshini.

5.Ulawulo lomgangatho kunye nokuhlolwa

Ukugcina imilinganiselo engqongqo yolawulo lomgangatho kuyo yonke inkqubo yokwenziwa kwemveliso ibalulekile kumatshini womatshini we-CNC ngokukhawuleza nangokuchanekileyo. Ukusebenzisa izixhobo zokuhlola eziphambili ezifanaukulungelelanisa oomatshini bokulinganisa(CMM) kunye neeprobes zokuskena zinokubonelela ngemilinganiselo echanekileyo yobukhulu kwaye incede ukufumanisa naziphi na iziphene okanye ukuphambuka kwiinkcukacha. Izixhobo zokusebenza kunye nezixhobo zokuhlola kufuneka zihlaziywe rhoqo kwaye ziqinisekiswe ukuze kuqinisekiswe ukuveliswa komgangatho ohambelanayo.

Isishwankathelo

Ukuvelisa iinxalenye zomatshini ezichanekileyo ze-CNC ziza nemingeni eyahlukahlukeneyo, kubandakanywa ukuntsokotha koyilo, ukukhethwa kwezinto eziphathekayo, amandla omatshini, izixhobo kunye nokulawula umgangatho. Ngokusombulula le mingeni, abavelisi banokuphucula ukusebenza kunye nokuchaneka kwemisebenzi yabo yomatshini.

Ukusebenzisana phakathi kweenjineli zoyilo, abadwelisi beprogram, abaqhubi boomatshini kunye nabasebenzi bokulawula umgangatho badlala indima ephambili ekoyiseni obu bunzima kunye nokuvelisa ngempumelelo iindawo ezichanekileyo ezikumgangatho ophezulu. Ikamva lokuchaneka ngokukhawuleza komatshini we-CNC likhangeleka lithembisa njengoko itekhnoloji kunye nobuchule buqhubeka nokuhambela phambili, ukuguqula ishishini kunye nokuvula amathuba amatsha okuvelisa.

Ixesha lokuposa: Oct-31-2023