I-Flatness lunyamezelo olubalulekileyo lwejometri kwi-machining, ngakumbi kwi-sheet metal kunye ne-CNC machining process. Ibhekisa kwimeko apho zonke iingongoma kumphezulu zilingana ukusuka kwinqwelomoya yesalathiso.

Ukufikelela kwi-flatness kubalulekile ngenxa yezi zizathu zilandelayo:

1. Ukusebenza okusebenzayo:Amalungu amaninzi kufuneka ahlangane ngokuchanekileyo. Ukuba iinxalenye azikho tyaba, zinokubangela ukungahambi kakuhle kwaye zichaphazele umsebenzi jikelele wendibano.

2. Ukuhanjiswa komthwalo:Umphezulu osicaba uqinisekisa ukuhanjiswa komthwalo. Imiphezulu engalinganiyo inokubangela uxinzelelo olunokubangela ukusilela kwangaphambi kwexesha.

3. Umgangatho wobuhle:Kumashishini apho imbonakalo ibalulekile, njengemoto kunye ne-electronics yabathengi, i-flatness inceda ukuphucula umtsalane obonakalayo wemveliso.

4. UFanelo lweNdibano:Amacandelo angalingani angenza nzima inkqubo yokuhlanganisana, okubangela ukunyuka kweendleko zabasebenzi kunye nexesha.

5. Ukuchaneka kumatshini ongaphaya:I-Flatness isoloko iyimfuneko kwimisebenzi yomatshini elandelayo efana nokubhola okanye ukugaya, apho umphezulu osicaba uyimfuneko ukufumana iziphumo ezichanekileyo.

Gcina ukuthambeka ngexesha lokucubungula

Ukufezekisa nokugcina i-flatness ngexesha lomatshini kufuna ukucwangciswa ngokucophelela kunye nokwenziwa. Nazi ezinye izicwangciso-qhinga:

1. Ukukhethwa kwezinto:Khetha izixhobo ekungekho lula ukuzijika okanye ukonakala ngexesha lokucubungula. Izinyithi ezine-coefficients ezisezantsi zokwandiswa kwe-thermal zikhethwa ngokubanzi.

2. Ulungiso oluchanekileyo:Sebenzisa izixhobo ezifanelekileyo ukuze ubambe ngokukhuselekileyo i-workpiece ngexesha lomatshini. Oku kunciphisa intshukumo kunye nokungcangcazela okunokubangela ukulwa.

3. Iiparamitha zoomatshini ezilawulwayo:Lungiselela isantya sokusika, ukutya kunye nobunzulu bokusika. Ubushushu obugqithisileyo obuveliswa ngexesha lokulungiswa kunokubangela ukwanda kwe-thermal kunye ne-warping.

4. Ukulandelelanisa Machining:Ukuba kunokwenzeka, iinxalenye zoomatshini ngokwezigaba. Oku kuvumela ukuba izinto eziphathekayo zisuswe ngendlela elawulwayo, ukunciphisa umngcipheko wokuguqulwa.

5. Unyango lwasemva kokulungiswa:Qwalasela iinkqubo zokunciphisa uxinzelelo ezinje nge-post-processing annealing or normalizing ukuphelisa uxinzelelo lwangaphakathi olunokubangela i-warpage.

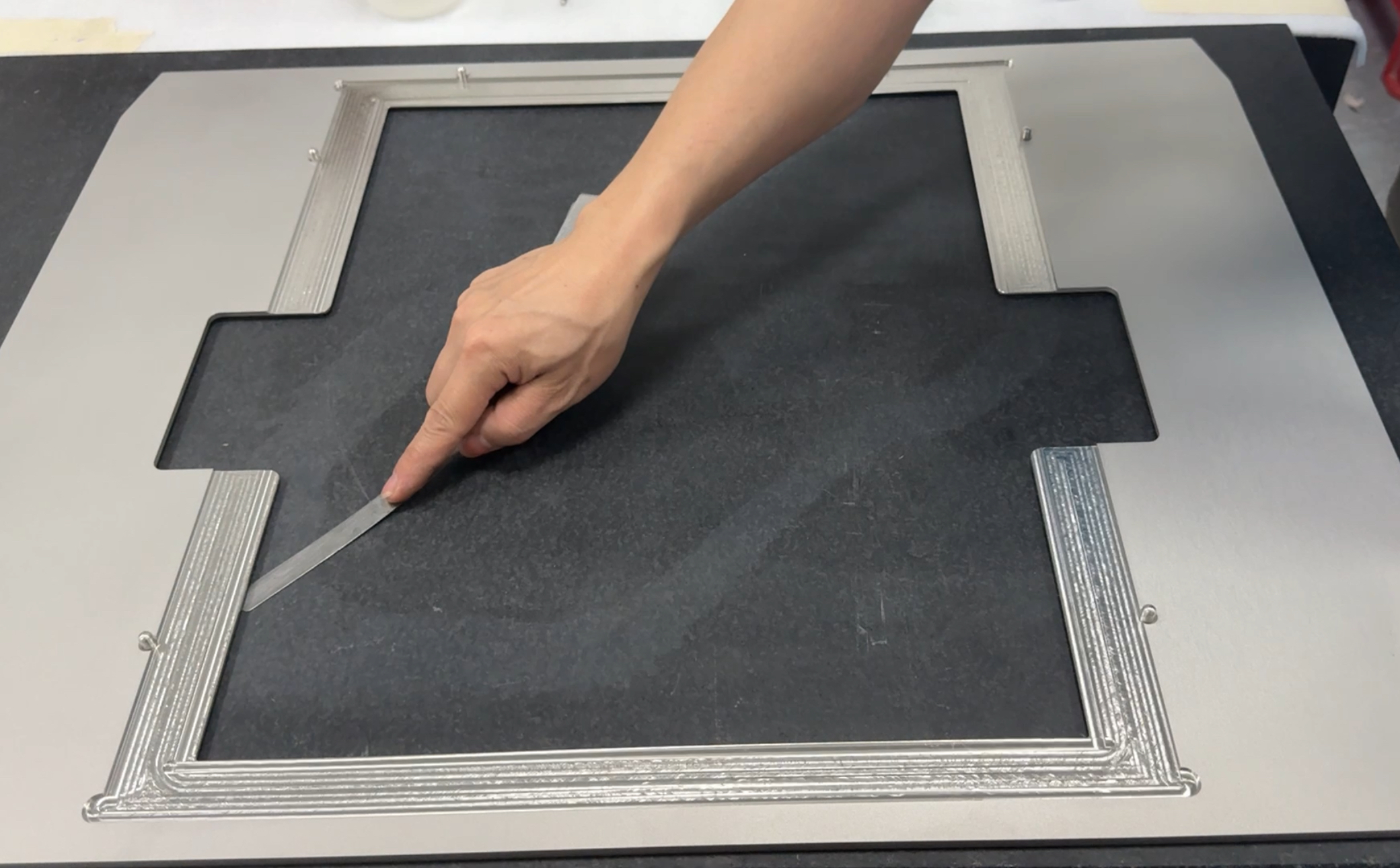

6. Ukusetyenziswa koMphezulu weReferensi oFlethi:Rhoqo ujonge kwaye ulungelelanise izixhobo zoomatshini ukuqinisekisa ukuba ziyasebenza kumphezulu wesalathiso osicaba.

Jonga ukuba tyaba

Ukuqinisekisa ukubaiindawo ezenziwe ngoomatshiniUkuhlangabezana neenkcukacha zokucaba, iindlela ezifanelekileyo zokuhlola kufuneka zisetyenziswe:

1. UHlolo oluBonakalayo:Ukuhlola okubonakalayo okulula ngamanye amaxesha kunokuveza imiba ecacileyo yokutya, njengezithuba phantsi kwenxalenye okanye ukukhanya okudlulayo.

2. Indlela yoMlawuli:Beka irula echanekileyo kumphezulu kwaye usebenzise igeyiji yokulinganisa ukulinganisa naziphi na izikhewu. Le ndlela iyasebenza kakhulu ekuhloleni ngokukhawuleza.

3. Isalathisi sokucofa:Isalathisi sokudayela singasetyenziselwa ukulinganisa ukuphambuka kwe-flatness yendawo yonke. Le ndlela inika imilinganiselo echanekileyo.

4. Ukulungelelanisa uMshini wokuMeta (CMM):Kwizicelo ezichanekileyo eziphezulu, i-CMM ingasetyenziselwa ukulinganisa ukunyanzeliswa kwendawo ngokuthatha amanqaku amaninzi kunye nokubala ukuphambuka kwinqwelo-moya.

5. Indlela ye-Optical Plane:Oku kubandakanya ukusebenzisa i-optical plane kunye nokukhanya kwe-monochromatic ukujonga ukukhanya. Iipateni zokuphazamiseka zingabonisa ukutenxa.

6. Ukuskena ngeLaser:Itekhnoloji yokuskena yelaser ekwinqanaba eliphezulu ibonelela ngeemephu zomhlaba ezineenkcukacha, ivumela uhlalutyo olubanzi lokutyaba.

Ukuququmbela

I-Flatness yinto ebalulekileyo yokucubungula, echaphazela ukusebenza, i-aesthetics kunye nokusebenza kakuhle kwendibano. Ngokuqonda ukubaluleka kwayo kunye nokuphumeza izicwangciso zokugcina kunye nokuhlola ukuthamba,I-HY METALS inokuqinisekisa ukuveliswa kwamacandelo aphezulu ahlangabezana nokunyamezela okuqinileyo. Ukuhlolwa rhoqo kunye nokuthotyelwa kweendlela zokuqhuba kakuhle kuya kuphucula ukusebenza kwemveliso kunye nokwaneliseka kwabathengi.

HY Iintsimbibonelelaindawo enye iinkonzo zokwenza isiko kuquka ukwenziwa kwamaphepha esinyithikwayeCNC Machining,14 iminyaka yamavakwayeZisi-8 izakhiwo ezizezabantu ngokupheleleyo.

EgqwesileyoUmgangathoulawulo, mfutshaneJika ujonge ngemva,kakhuluunxibelelwano.

Thumela eyakhoRFQ ngeimizobo eneenkcukacha namhlanje. Siza kukucaphulela ngokukhawuleza.

WeChat:na09260838

Xelela:+86 15815874097

I-imeyile:susanx@hymetalproducts.com

Ixesha lokuposa: Oct-10-2024