Kumacandelo esinyithi eShithi, ukongeza izinto eziqinileyo zibalulekile ekuqinisekiseni amandla kunye nokuqina kwazo. Kodwa yintoni iimbambo, kwaye kutheni zibaluleke kangaka kwiphepha lentsimbi? Kwakhona, sizenza njani iimbambo ngexesha leprototyping ngaphandle kokusebenzisa izixhobo zesitampu?

Okokuqala, makhe sichaze ukuba yintoni ubambo. Ngokusisiseko, ubambo sisicangca esithe tyaba, esithe kratya sidityaniswe nenxalenye yentsimbi, ngokuqhelekileyo isezantsi okanye ngaphakathi. Ezi zakhiwo zinika amandla okongeziweyo kunye nokomelela kwinqanaba, ngelixa likwakhusela ukuguqulwa okungafunekiyo okanye ukulwa. Ngokudibanisa iimbambo, iinxalenye zentsimbi ziyakwazi ukumelana nemithwalo emikhulu kunye noxinzelelo, okwenza ukuba zithembeke kwaye zihlale zihlala.

Ngoko, kutheni kufuneka songeze iimbambo kwiindawo zentsimbi? Impendulo ixhomekeke kubunzima bala macandelo. Amacandelo esinyithi ahlala ephantsi kwamandla ahlukeneyo, kuquka ukugoba, ukujija, kunye nokunyathela. Ngaphandle kokuqiniswa okwaneleyo, la macandelo anganikezela ngokukhawuleza kula mandla, abangele ukusilela okanye ukuphuka. Iimbambo zibonelela ngenkxaso eyimfuneko kunye nokuqiniswa kokuthintela iingxaki ezinjalo ukuba zenzeke.

Ngoku, masiye kwinqanaba leprototyping. Kumanqanaba okuqala ophuhliso, kubalulekile ukudala kunye nokuvavanya iinguqulelo ezahlukeneyo zamacandelo esinyithi ngaphambi kokuveliswa kothotho. Le nkqubo idinga ukuchaneka, ukuchaneka kunye nesantya. Ngokuqhelekileyo, ukudala iimbambo ngexesha leprototyping kufuna ukusetyenziswa kwezixhobo zesitampu, ezinokubiza kwaye zichithe ixesha. Nangona kunjalo, kukho enye indlela yokwenza iimbambo ngexesha leprototyping stage - ngezixhobo ezilula.

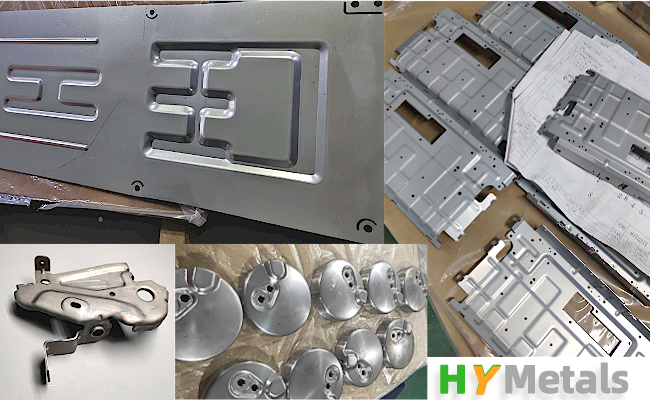

Kwa-HY Metals, sisebenza ngokukhethekileyo ekwenzeni iphepha lesinyithi elichanekileyo, kubandakanywa ukwenziwa kwamawaka eentsimbi zentsimbi yemoto. Ngethuba lesigaba seprototyping, senza iimbambo ngokusebenzisa izixhobo ezilula kwaye zihambelana nemizobo. Siyiprotoyipu ngononophelo iinxalenye zentsimbi kwaye siqinisekisa ukuba iziqina zibonelela ngamandla ayimfuneko kunye nokomeleza okufunekayo. Ngokusebenzisa izixhobo ezilula ngexesha leprototyping yeqonga ukwenza i-ribbed sheet metal parts, sinokunciphisa ixesha kunye neendleko ezifunekayo kwi-stamping tooling.

Isishwankathelo, ukongeza i-stiffener kumacandelo esinyithi kubalulekile ekwandiseni amandla kunye nokuqina. Ubunzima bamacandelo entsimbi bufuna ukuqiniswa okwaneleyo ukukhusela i-deformation engafunekiyo okanye i-warping. Ngexesha leprototyping, iinguqulelo ezahlukeneyo zamacandelo esinyithi kufuneka zenziwe kwaye zivavanywe ngelixa kugcinwa ixesha elininzi kunye neendleko. I-HY Metals inamava kunye nobuchule bokwenza iinxalenye zentsimbi ye-ribbed sheet ngaphandle kokusetyenziswa kwezixhobo ezixabisa izitampu. Ngokusebenzisa izixhobo ezilula, sinokuhlangabezana neemfuno ezichanekileyo zecandelo ngalinye lesinyithi ngelixa sigcina abathengi bethu ixesha kunye nemali.

Ixesha lokuposa: Mar-25-2023