Eminye imisebenzi yentsimbi yesiko kubandakanya iAluminiyam extrusion kunye ne-die-casting

I-HY Metals ikhethekileyo kwisiko kuzo zonke iintlobo zentsimbi kunye namalungu eplastiki.

Sinezethu iivenkile zentsimbi kunye neevenkile zomatshini ze-CNC, sikwanazo nezibonelelo ezininzi ezigqwesileyo nezingabizi kakhulu kwezinye izinto zentsimbi kunye neplastiki efana ne-extrusion, i-die casting, i-spinning, ukwenza ucingo kunye nenaliti yeplastiki.

I-HY Metals inokusingatha ulawulo olupheleleyo lwekhonkco lokubonelela ngesinyithi sakho esiko kunye neeprojekthi zeplastiki ukusuka kwimathiriyeli ukuya kwinqanawa.

Ke ukuba unayo nayiphi na imisebenzi yesinyithi neyeplastiki yesiko, thumela kwi-HY Metals, siya kubonelela ngenkonzo yokumisa enye.

IAluminiyam Extrusion

Ukwakhiwa kunye nokuhlobisa iiprofayili eziqhelekileyo ze-aluminium zixhaphake kakhulu kwimarike yendawo yethu.

I-HY Metals ayikho kule ndawo yeprofayili eqhelekileyo.

Sikhethekileyo kwiprofayili ye-aluminium yesiko okanye iprofayili ye-aluminium edla ngokusetyenziswa kwimveliso yethu ukunceda inkqubo yomatshini we-CNC ngexabiso eliphantsi.

Kwimilo ethile ekhethekileyo yeradiyetha okanye iityhubhu zealuminiyam ezenzelwe wena nazo zinokukhutshelwa emva koko zenziwe ngoomatshini kwimizobo.

Logama nje icandelo elifanayo lomthamo ophantsi okanye imveliso yobuninzi aluminiyam amacandelo ngomatshini, singenza kubo nge extrusion ke CNC inkqubo machining ukugcina ixesha kunye neendleko machining.

I-extrusion yesiko iya kufuna i-extrusion tooling kuqala. Ukusetyenziswa kwezixhobo ngokuqhelekileyo akubizi kakhulu xa kuthelekiswa nokubunjwa okanye ukutofa.

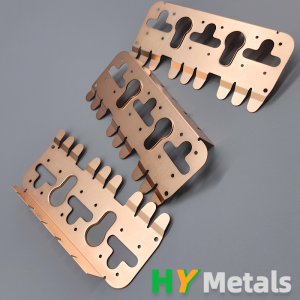

Umfanekiso 2:Amanye amacandelo e-aluminiyam enziwe nge-HY Metals

Umzekelo, iindawo zetyhubhu ezi-3 zokugqibela kulo mfanekiso zakhutshelwa ityhubhu ende ekhethekileyo kuqala kwaye emva koko ngomatshini imingxuma kunye nokunqunyulwa ngokomzobo. Senze i-extrusion tooling yale nxalenye kuba akukho bukhulu obunjalo kunye nemilo yetyhubhu kwimarike.

Extrusion + CNC machining sesona sisombululo kule nxalenye.

Die Casting

I-Die casting yinkqubo yokuphosa isinyithi, ebonakala ngokusetyenziswa kwe-mold cavity ukufaka uxinzelelo oluphezulu kwintsimbi etyhidiweyo. I-Die for casting okanye ebizwa ngokuba yi-Mold of casting ihlala yenziwe ngee-alloys ezinamandla.

I-Metal Die casting ifana nokubumba inaliti. Uninzi lwezixhobo zokuphosa intsimbi azinazinki, njengeZinc, iCopper, iAluminium, iMagnesium, iLead, iTin, kunye nealloyi yeLead-tin.

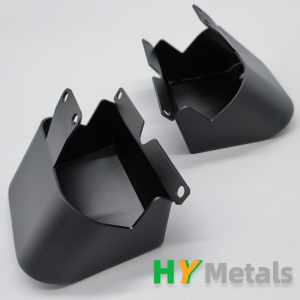

Umfanekiso wesi-3: Inxalenye yokuphosa ukufa.

Iinkqubo ze-Die-casting zisetyenziselwa ukuveliswa kobuninzi kwi-QTY enkulu kunye nobukhulu obuncinci kunye nobukhulu obuphakathi ngenxa yeendleko eziphezulu zokungunda. Xa kuthelekiswa nenye inkqubo yokuphosa, ukuphosa kufa kunomphezulu othe tyaba kunye nokuhambelana komgangatho ophezulu.

Kwimisebenzi yethu yesinyithi echanekileyo, sihlala sisenza iinxalenye zokuphosa emva koko i-CNC yenziwe ngomatshini ukufumana iindawo ezigqityiweyo.

Ukuqulunqa ucingo kunye neNtwasahlobo

Ukwenza ucingo kunye nemithombo nayo yinkqubo eqhelekileyo kwiiprojekthi ezininzi zeshishini.

Singenza zonke iintlobo zocingo ezenza kuquka intsimbi, intsimbi engatyiwa, ubhedu.

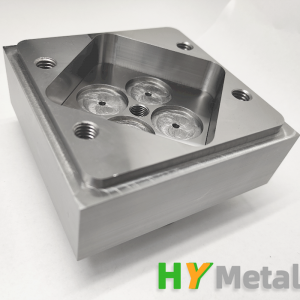

Umfanekiso wesi-4: Iingcingo ezenziwe ngeingcingo kunye nemithombo yi-HY Metals

Ukujikeleza

Ukuphotha kukubeka ipleyiti ecaba okanye izinto ezingenanto kwi-axis spindle yomatshini wokusonta ukwenza i-cylindrical, conical, formation parabolic okanye ezinye iindawo ezigobileyo. Iindawo ezijikelezayo zeemilo ezintsokothileyo zinokusetyenzwa ngokusonta.

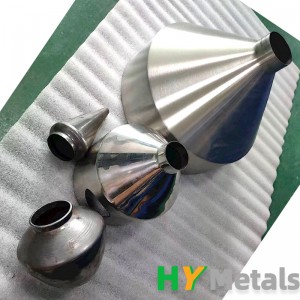

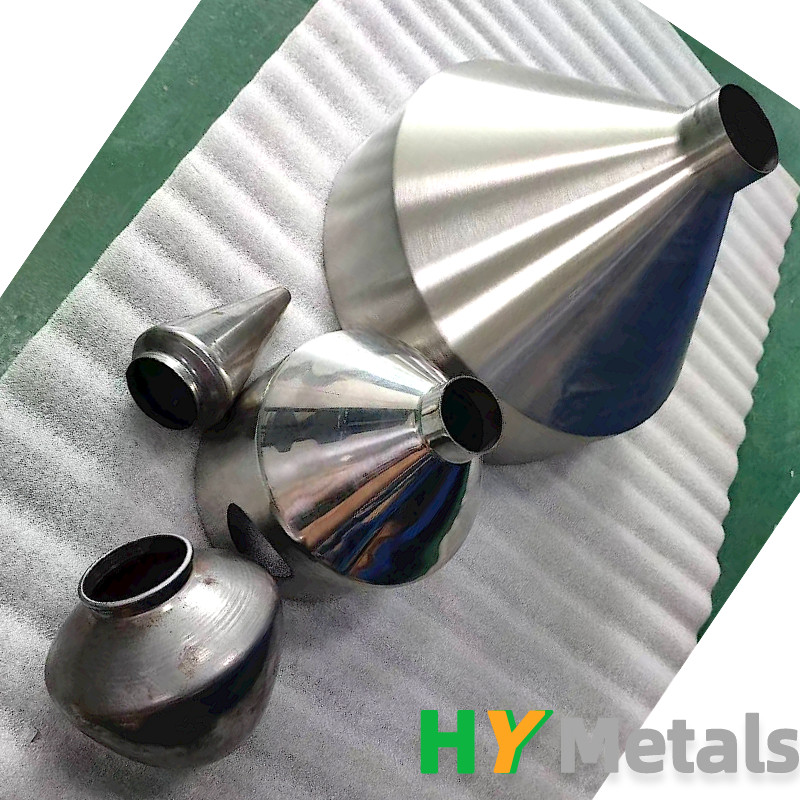

Umboniso5:Ezinye iimveliso zokusonta nge-HY Metals

Ngenxa yonyamezelo olurhabaxa, inkqubo yeSpinning ayisetyenziswa kangako kwimveliso yethu.

Ngamanye amaxesha abathengi bethu kwifenitshala okanye kwishishini lokukhanyisa i-odolo yesibane isigqubuthelo kuthi. Sidla ngokwenza amaqweqwe ngokusonta.