Iinkqubo zokusika isinyithi ezichanekileyo ezibandakanya ukusika iLaser, iChemical etching kunye neJet yaManzi

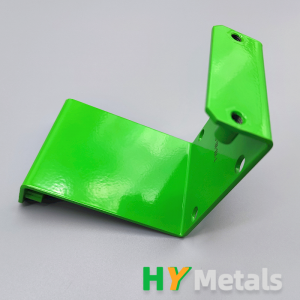

IiNkqubo zokuFakwa kweShithi: Ukusika, ukugoba okanye ukuBumba, ukucofa okanye ukuRiveta, ukuwelda kunye neNdibano.

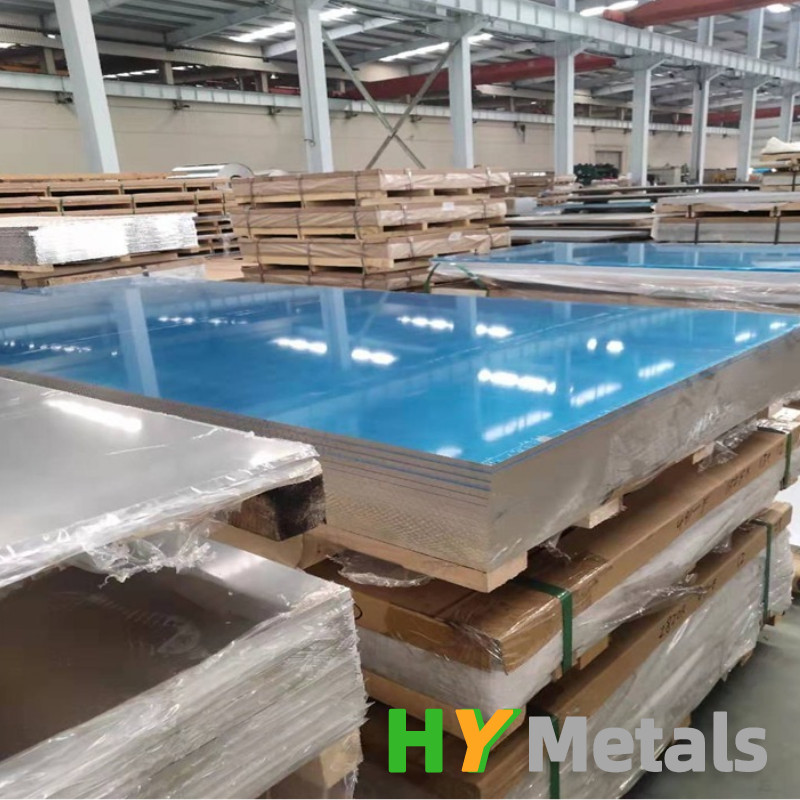

Izinto zentsimbi zentsimbi zidla ngokuba ziipleyiti zetsimbi ezinobukhulu be-1220 * 2440mm, okanye imiqulu yesinyithi enobubanzi obuchaziweyo.

Ngoko ke ngokweenxalenye ezahlukeneyo zentsimbi yesiko, inyathelo lokuqala liya kunqunyulwa imathiriyeli ukuya kubungakanani obufanelekileyo okanye ukusika ipleyiti yonke ngokwepateni ecaba.

Kukho iintlobo ezi-4 eziphambili zeendlela zokusika kumacandelo entsimbi:Ukusika iLaser, ijethi yamanzi, iChemical etching, stamping cut with tooling.

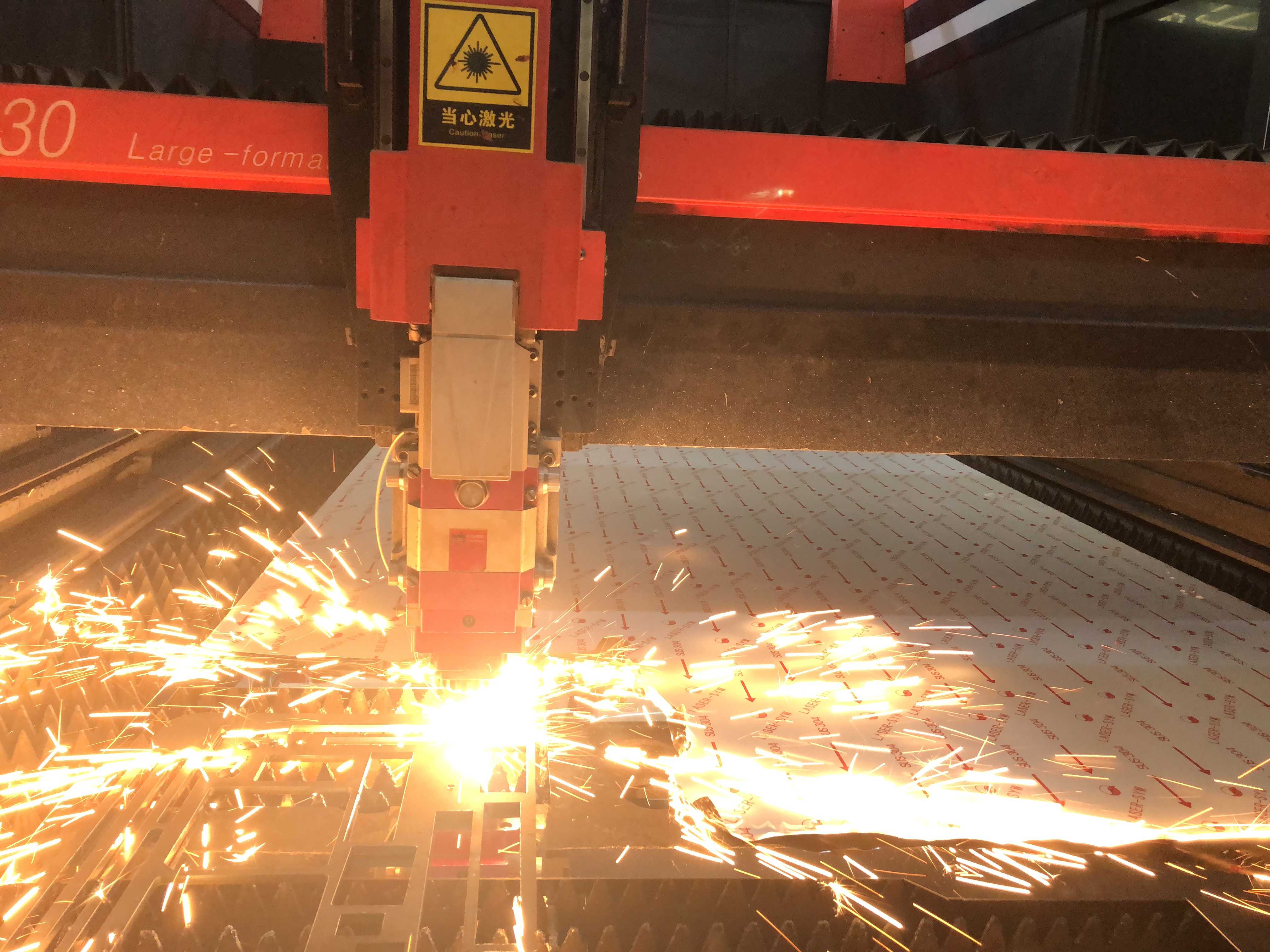

1.1 Ukusika iLaser

Ukusika i-laser yindlela esetyenziswa kakhulu yokusika i-sheet metal, ngakumbi iprototypes yentsimbi echanekileyo kunye nokuveliswa komthamo ophantsi, kunye nenye imathiriyeli eshinyeneyo engafanelanga ukusika isitampu.

Kwimveliso yethu eqhelekileyo, ngaphezu kwe-90% yokusika i-sheet sheet isetyenziselwa ukusika i-laser. Ukusika kweLaser kunokufumana ukunyamezela okungcono kunye nemiphetho egudileyo ngakumbi kunejethi yamanzi. Kwaye ukusika kweLaser kufanelekile kwaye kuguquguquka kwizinto ezininzi kunye nobukhulu kunezinye iindlela.

I-HY Metals inemishini yokusika i-laser ye-7 kwaye inokusika izinto ezifana neNsimbi, i-Aluminiyam, ubhedu, insimbi engenasici kunye nobubanzi obuyi-0.2mm-12mm.

Kwaye sinokubamba ukunyamezela kokusika njenge ± 0.1mm. (Ngokutsho komgangatho we-ISO2768-M okanye ongcono)

Kodwa ngamanye amaxesha, ukusika nge-laser kukwanezinto ezingeloncedo ezifana nokutshintsha ubushushu bezinto ezicekethekileyo, ii-burrs kunye nemiphetho ebukhali yobhedu olungqingqwa kunye nentsimbi eshinyeneyo yealuminium, ecothayo kwaye ibiza kakhulu kunokusika isitampu sokuvelisa ngobuninzi.

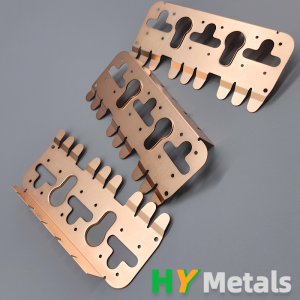

1.2 Ukufakwa kweekhemikhali

Ngobunzima beshiti lentsimbi ecekeceke kune-1mm, kukho enye inketho yokusika ukunqanda ukuguquka kobushushu belaser.

I-Etching luhlobo lwesuti yokusika ebandayo yeendawo ezincinci zetsimbi ezinemingxuma emininzi okanye iipateni ezintsonkothileyo okanye iipateni ezinesiqingatha.

1.3 Ijethi yamanzi

Ijethi yamanzi, eyaziwa ngokuba yi-water cut, iteknoloji yokusika ijethi yamanzi. Ngumatshini osebenzisa amanzi oxinzelelo oluphezulu ukusika. Ngenxa yexabiso layo eliphantsi, ukusebenza ngokulula kunye nesivuno esikhulu, ukusika amanzi ngokuthe ngcembe kuba yindlela yokusika yesiqhelo ekusikeni kwimizi-mveliso, ngakumbi ukusika izinto ezishinyeneyo.

Ijethi yamanzi ayiqhelekanga ukusetyenziswa kumgangatho wentsimbi echanekileyo ngenxa yesantya sayo esicothayo kunye nokunyamezelana.

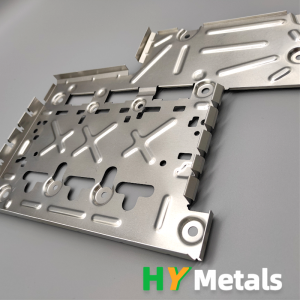

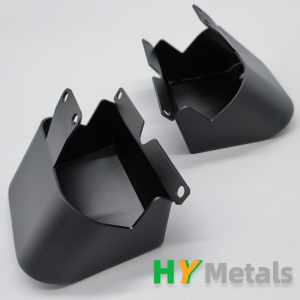

1.4 Ukusika isitampu

Ukusika isitampu yeyona ndlela isetyenziswa ngokuqhelekileyo emva kokusika i-laser, ngakumbi ukuveliswa kobuninzi kunye ne-QTY ngaphezu kwe-1000 pcs.

Ukusika isitampu yeyona ndlela ilungileyo yezinye iinxalenye ezincinci zetsimbi ezinokusikwa okuninzi kodwa ulandelelwano olukhulu. Ichaneke ngakumbi, ikhawuleza, inexabiso eliphantsi kwaye imiphetho igudile.

Iqela le-HY Metals liya kuhlala likunika eyona ndlela ifanelekileyo yokusika kwiiprojekthi zakho zentsimbi ngokweemfuno zakho ezidityaniswe namava ethu obuchule.